We can also supply complete air caster transport systems. A few examples are roll transporters, mobile cranes, beams and transport platforms. Click the link below to fill out the request sheet and we will come back to you with a proposal.

Have you ever wondered how heavy machinery is moved from one place to another? Whether it is a heavy boiler, transformer or a rocket – modern day machines are often very big and heavy. This can cause some issues when it comes to transport by manpower or traditional equipment designed to lift, such as a crane. At Hover Transport Systems, we offer a wide range of industrial equipment movers and other transport system solutions.

Hover Transport Systems is a Netherlands-based company specializing in the production, sales and repair of air skates. These industrial equipment movers are known under a multitude of names: air skates, air cushions, air bearings, air skids… No matter what you prefer to call them, our air skates are designed to move heavy equipment. They provide a modern and sustainable alternative to the traditional wheels used for the transportation of heavy equipment. The way the casters move heavy equipment is similar to hovercraft transport, hence our name.

Now that you’ve read all about the advantages of heavy load moving skates, surely you’ll be curious about when to use them. As previously mentioned, a single moving skate can carry an incredible weight up to 40.000 kilograms. However, this isn’t always necessary. You can check the Hover Transport Systems webshop to see all the different products we offer, the smallest ones starting at 110 to 225 kilograms. This means our high quality air skates can be utilized not only in factories, but also for moving heavy loads like theatre equipment, artifacts, movie props or warehouse machinery and equipment. Our air skates are also useful for relocation services, for example for machinery relocation. Hover Transport Systems offers an intelligent transportation system for every industrial moving issue you or your business might be facing!

Now you know where to look on our website, let’s have a look at some of the high quality air skates Hover Transport Systems has to offer*.

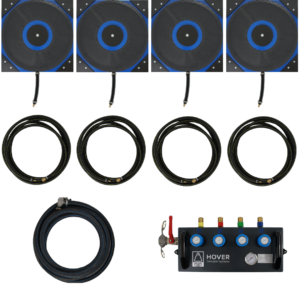

When you look at the webshop, you’ll see some handy filters focusing on weight, the amount of air skates, and a range of product categories which also includes Do It Yourself (DIY) air caster systems. If you’re looking for the latter, our DIY System 4 Polyurethane air casters 900KG might be for you. This system consists of 4 air skates and can handle a loading capacity of up to 900 kg.

If instead you’re looking for a complete modular system for moving heavy equipment, we’d suggest the Air Caster Neoprene 1.000KG as an alternative. Our largest air skid is the Air Caster Neoprene 40.000KG. We offer just about anything in between too, so don’t waste a second and visit the store now!

*Prices available upon request. If you’re looking for specifications, instructions and instruction videos, our website also offers those. Should you have any further questions, please do not hesitate to contact us. Our website also displays a selection of our worldwide partner network if you’re looking to order outside of Europe.

Loads are lifted from underneath so there is no risk of heavy objects falling down. There are no harmful exhaust gasses, just air.

Air skates are almost wear free and cost a fraction of alternative transport methods. We also repair and recondition broken air skates.

You just need compressed air and a suitable floor. No permanent constructions, complex software, electronics or power supply needed.

Air casters

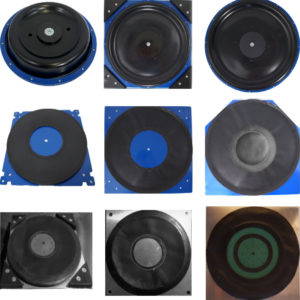

Air casters are the core elements in an air bearing system. These are the hovering and pneumatic lifting parts which consists of a metal backplate with a torus or bladder. The bladder / torus is either made from neoprene rubber or polyurethane plastic. The benefit of plastic is that it's almost wear free, but it has less capacity. Neoprene has almost twice the capacity and can generate a higher lift.

More information

Air caster systems

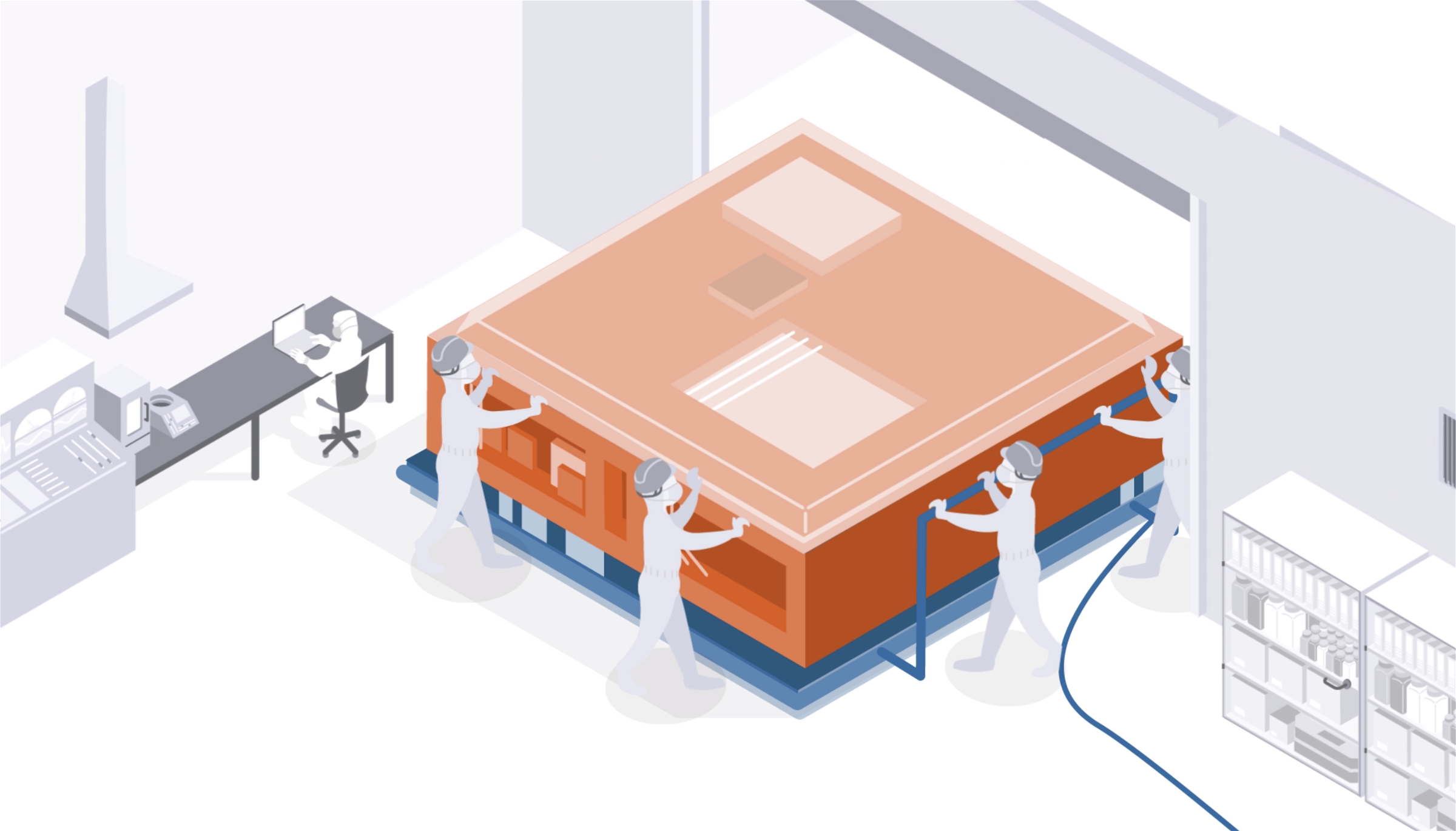

Moving heavy equipment can be a challenge. Especially if you’re dealing with fragile loads. Let us be the bearer of good news: our air caster system (or air bearing system) can ease this process in a safe, fast and simple way. You simply place the air caster rigging system underneath the object you want to transport. Connect it to your air supply system and easily move the load within minutes!

More information

Repairs, Spares, Services

In order to keep your air caster (systems) in optimum condition, we provide these services for all types of air casters from all manufacturers : - Preventive air caster inspection - Air caster repairs (tread replacement) - Complete rubber bladder (torus bag) exchange - Supply air caster and other pneumatic spare parts - Designated or consignment stock on-site - Full service contract Our air caster parts and systems are fully interchangeable with other brands as well. This will definitely help you save costs.

The usability of air casters is endless because there are so many advantages. We just want to sum up a few popular examples.

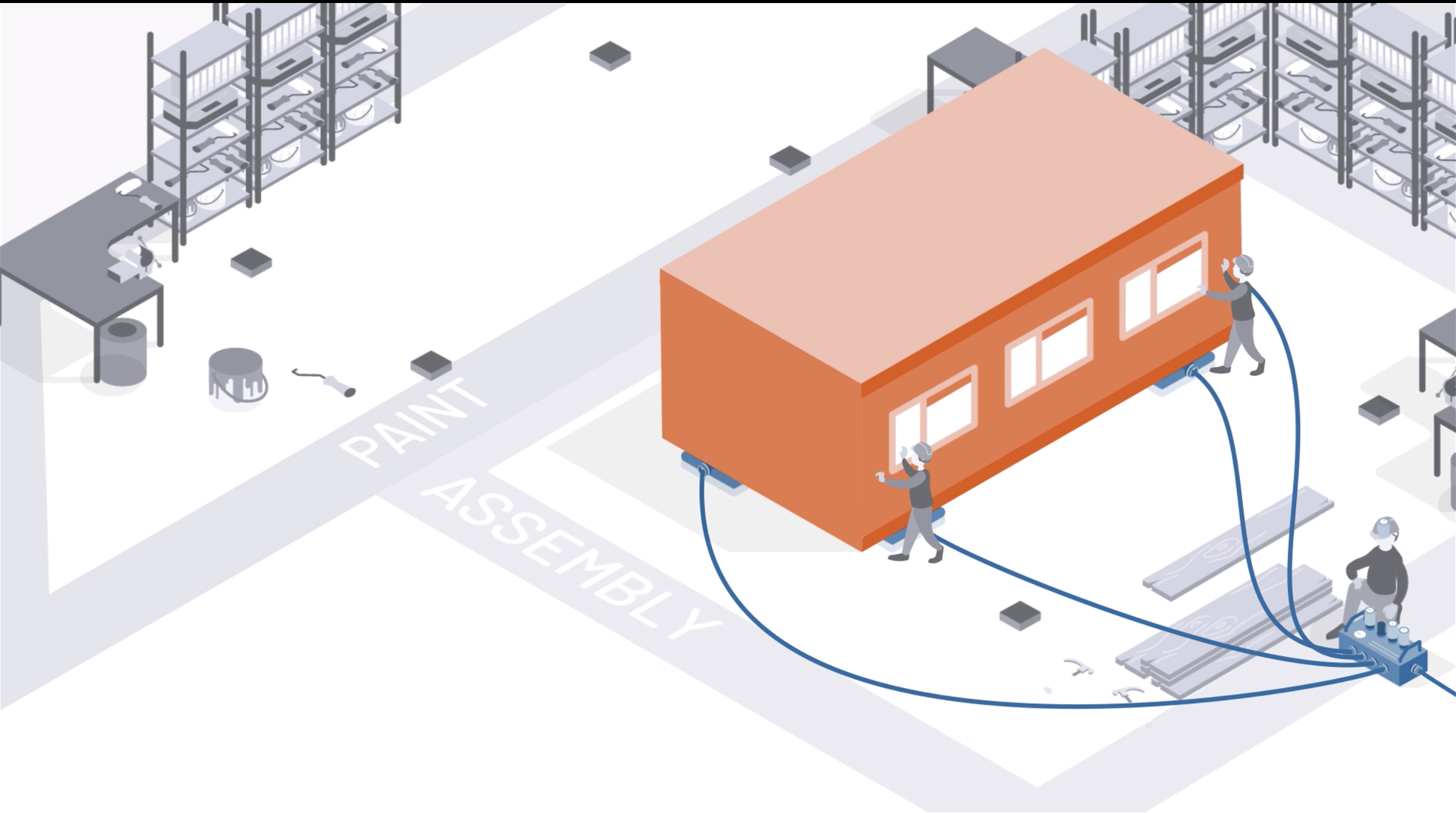

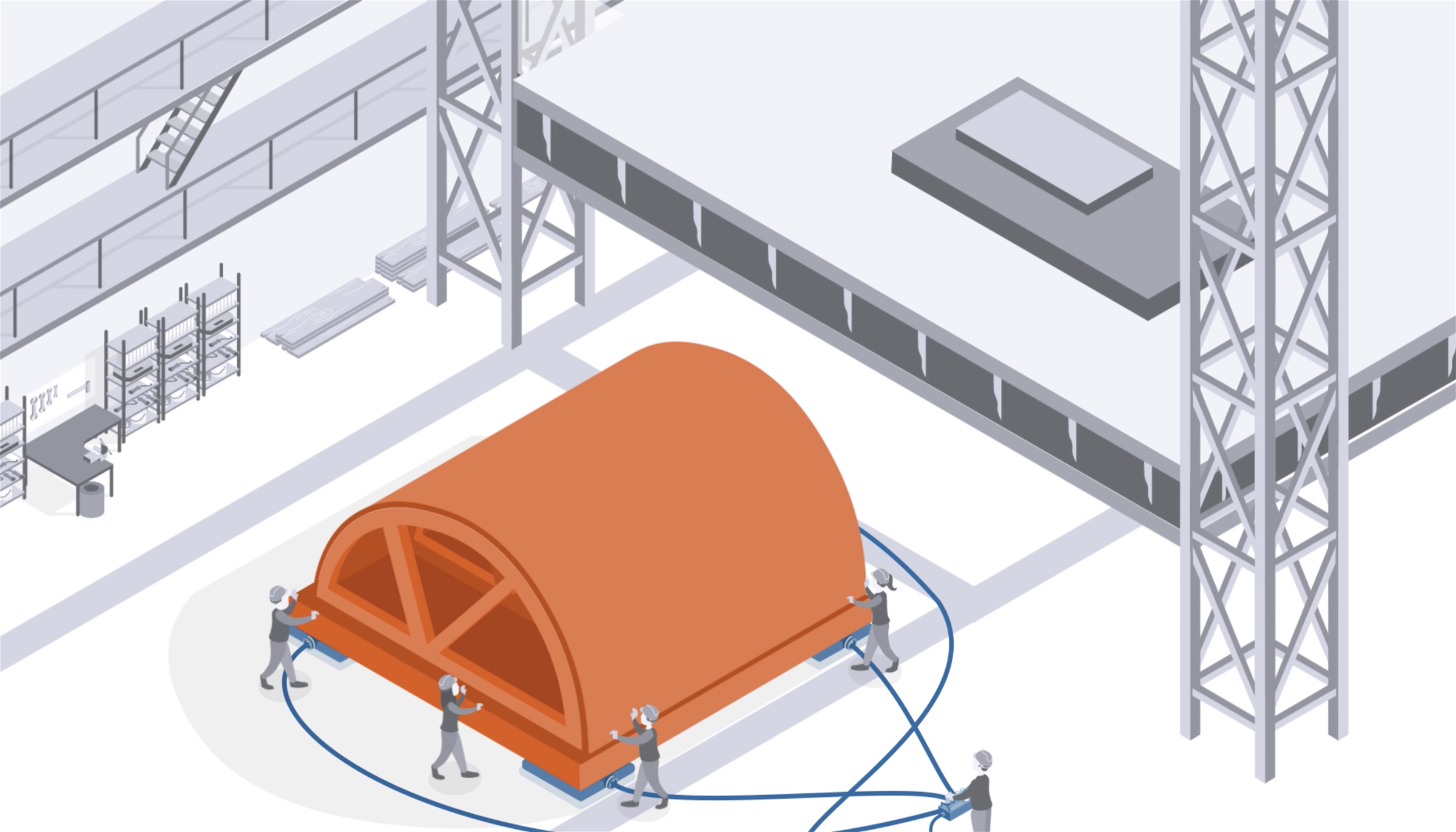

Air caster transport systems are used in modular building factories to easily move the structures between the different production stations. This reduces the transport time by 40% compared to traditional methods. The working staff can move the structures themselves in an ergonomic way. No permanent installations needed.

Air Caster Modular Systems

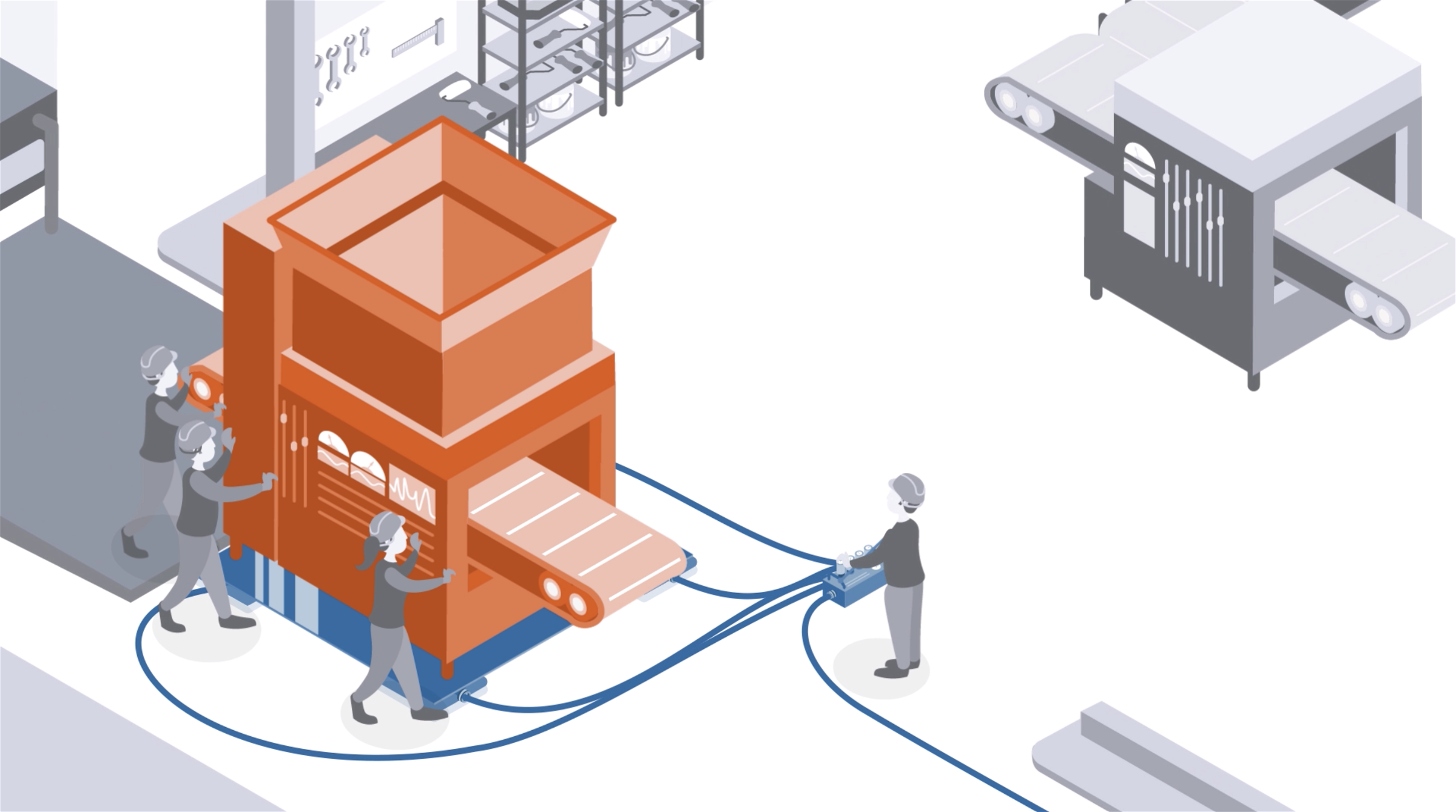

Air caster transport systems are used to relocate or install large and heavy machines. Compared to traditional methods this only takes a fraction of the time. Both the movement and final positioning are quicker because the system hovers above the floor. After the movement the system can easily be stored in the transport case.

Air Caster Modular Systems

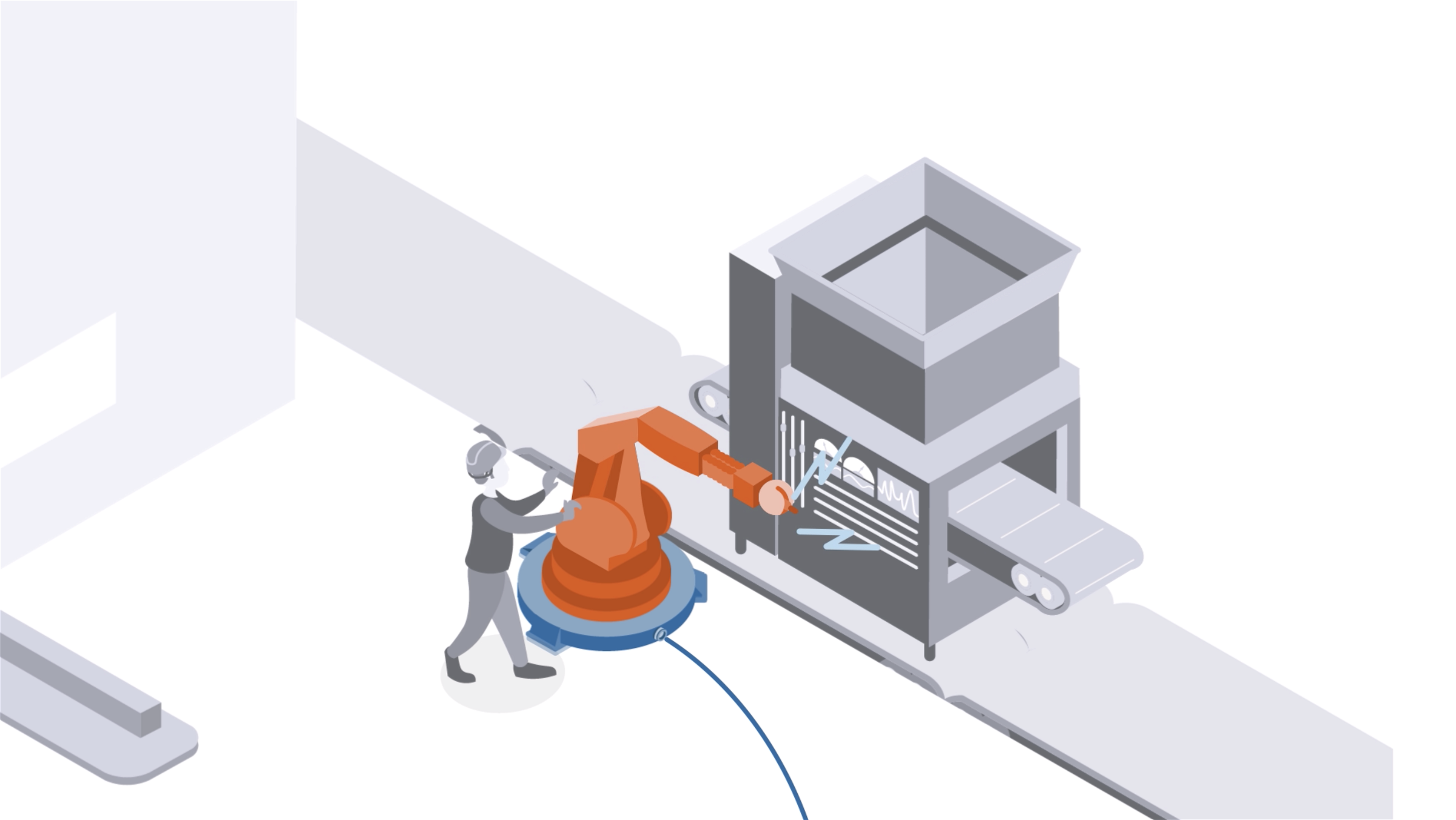

Air caster DIY systems are permanently installed into some heavy or large production tools. This makes the production process more flexible to better meet the markets requirements. Because the air casters are embedded in the tools, you just need to connect the air supply and the system is ready to go.

Air Caster DIY Systems

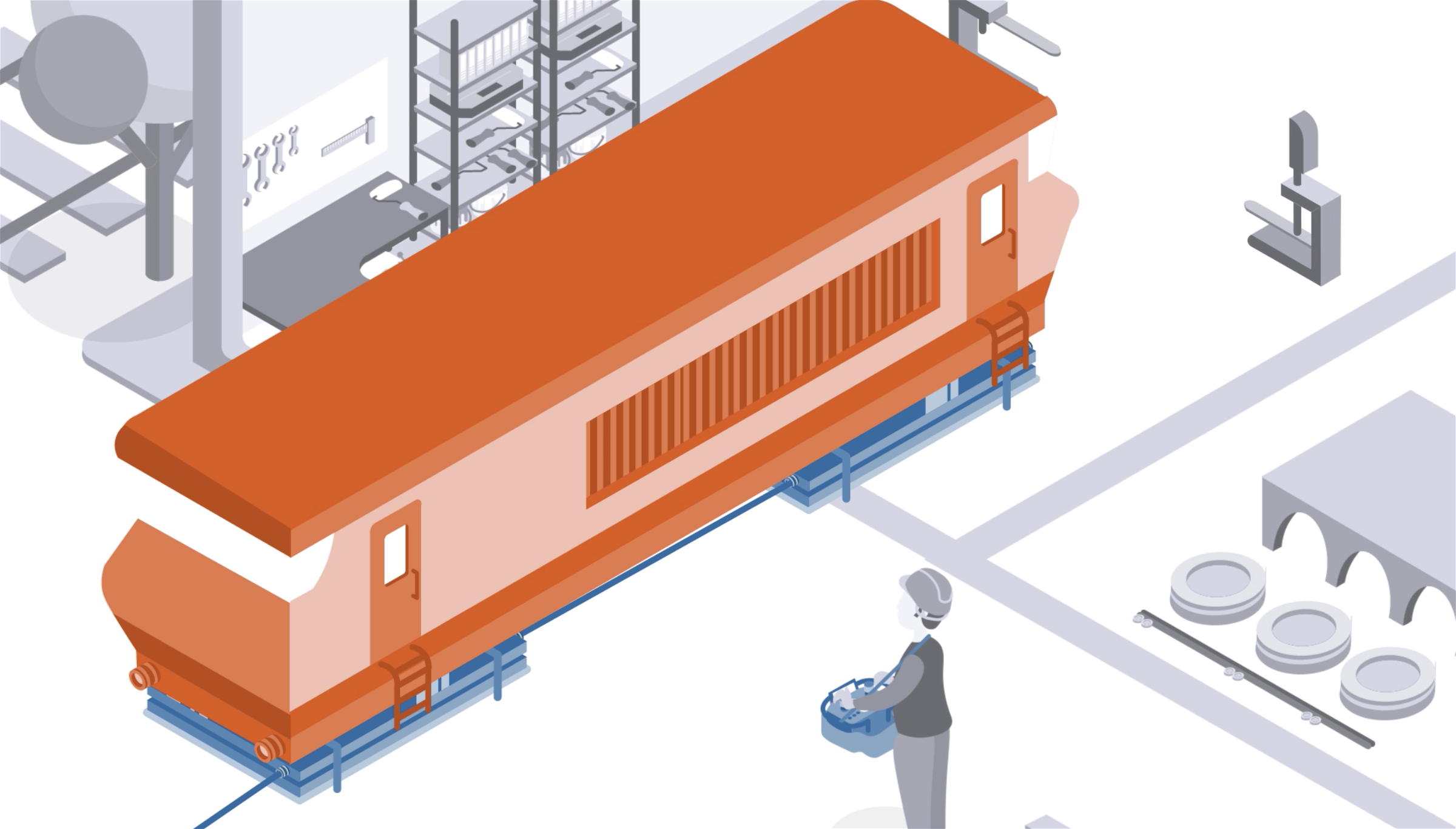

Air caster transport devices are used to move heavy locomotives and other vehicles during production or revision. Both the vehicles and their often heavy parts are transported very efficiently because of the high capacity and freedom of movement of the air casters. This saves time (often up to 30%) and prevents floor damage.

Air Caster DIY Systems

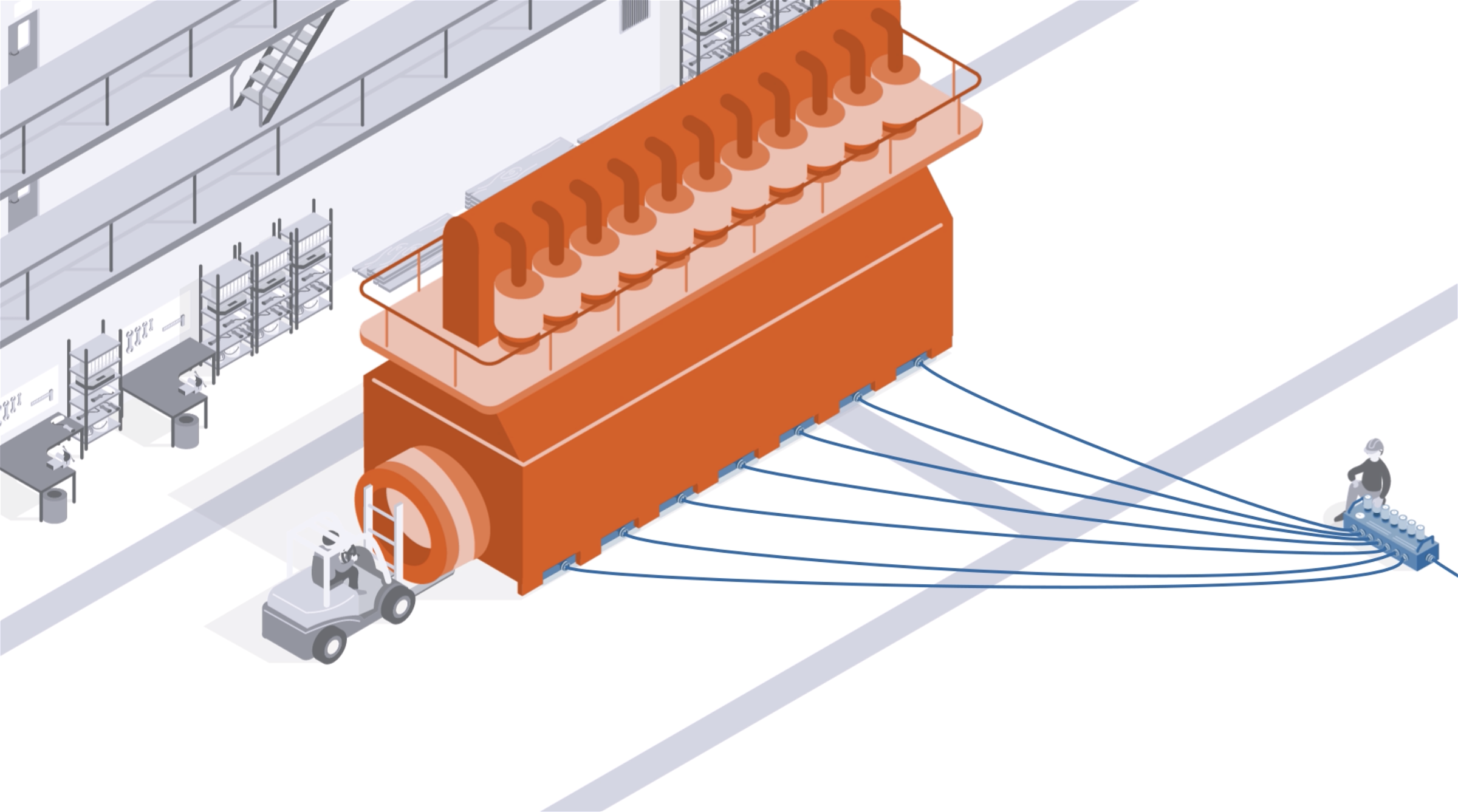

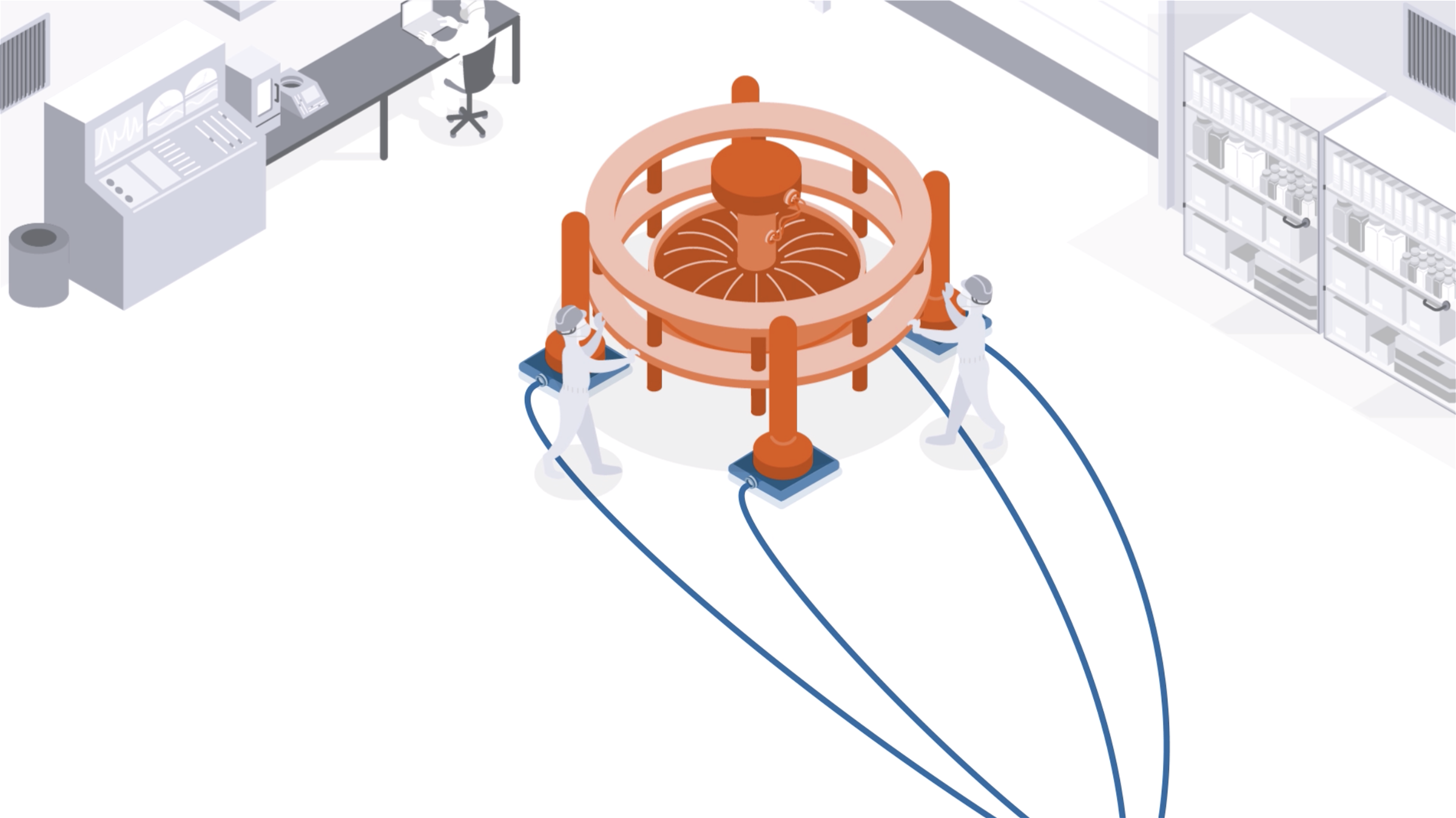

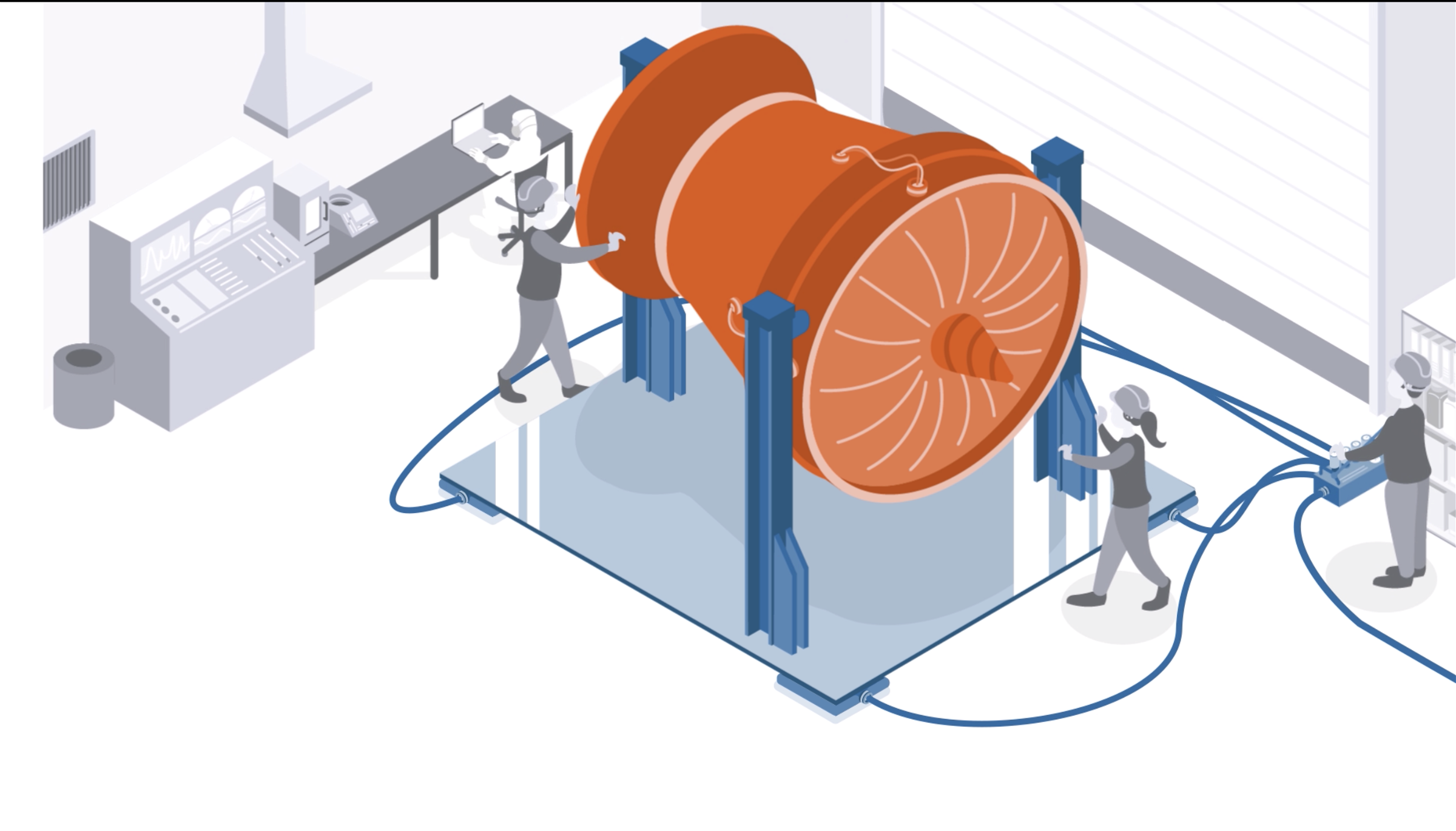

Air caster transport systems are used to move big engines and parts during production or revision. Big engines often have heavy parts that need to be placed very accurately. The use of air casters saves a lot of time in the (final) positioning of these parts because of the omnidirectional movement. Takes less time and less manpower.

Air Caster Modular Systems

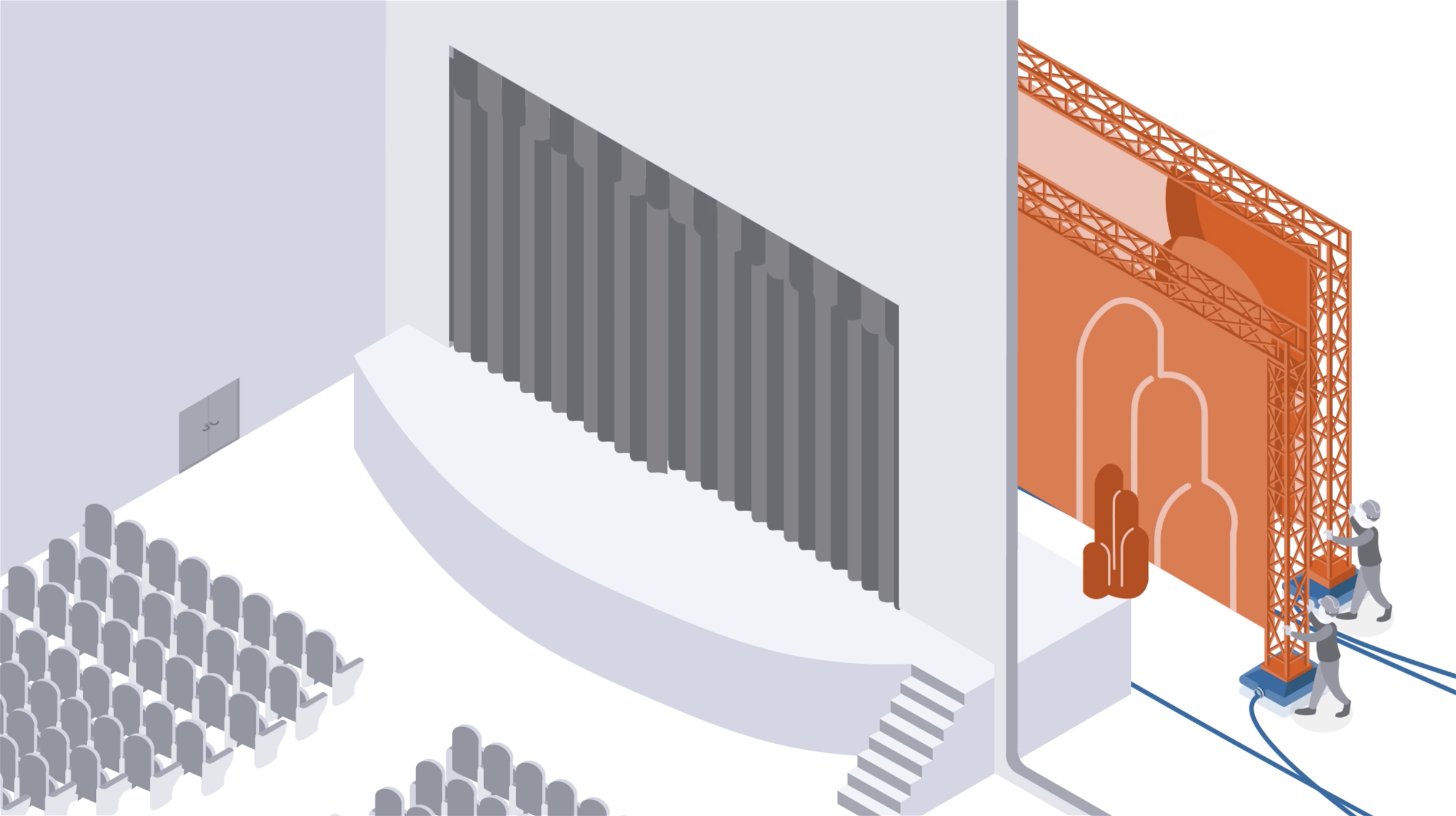

Air caster DIY systems are used to move theatre sceneries behind the curtains. The changement can be performed very quickly because the air casters are already installed and can be moved by the theatre staff themselves. In an ergonomic way because of the low friction of the system.

Air Caster DIY Systems

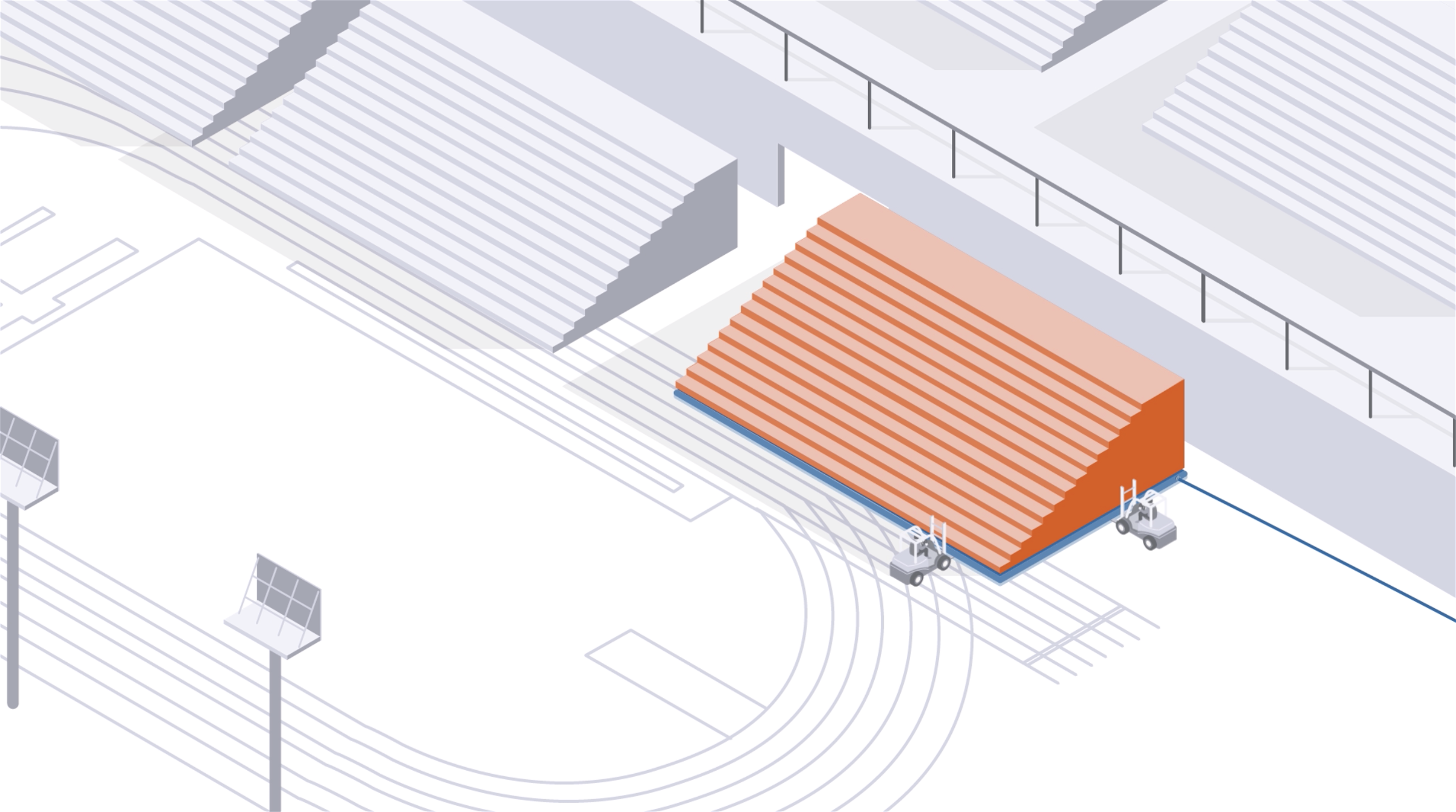

Air caster DIY systems are used to move big stadium seating modules. The change over time between different stadium setting is crucial in making a stadium multi purpose. These changes can be made quicker using air caster technology, up to 40%.

Air Caster DIY Systems

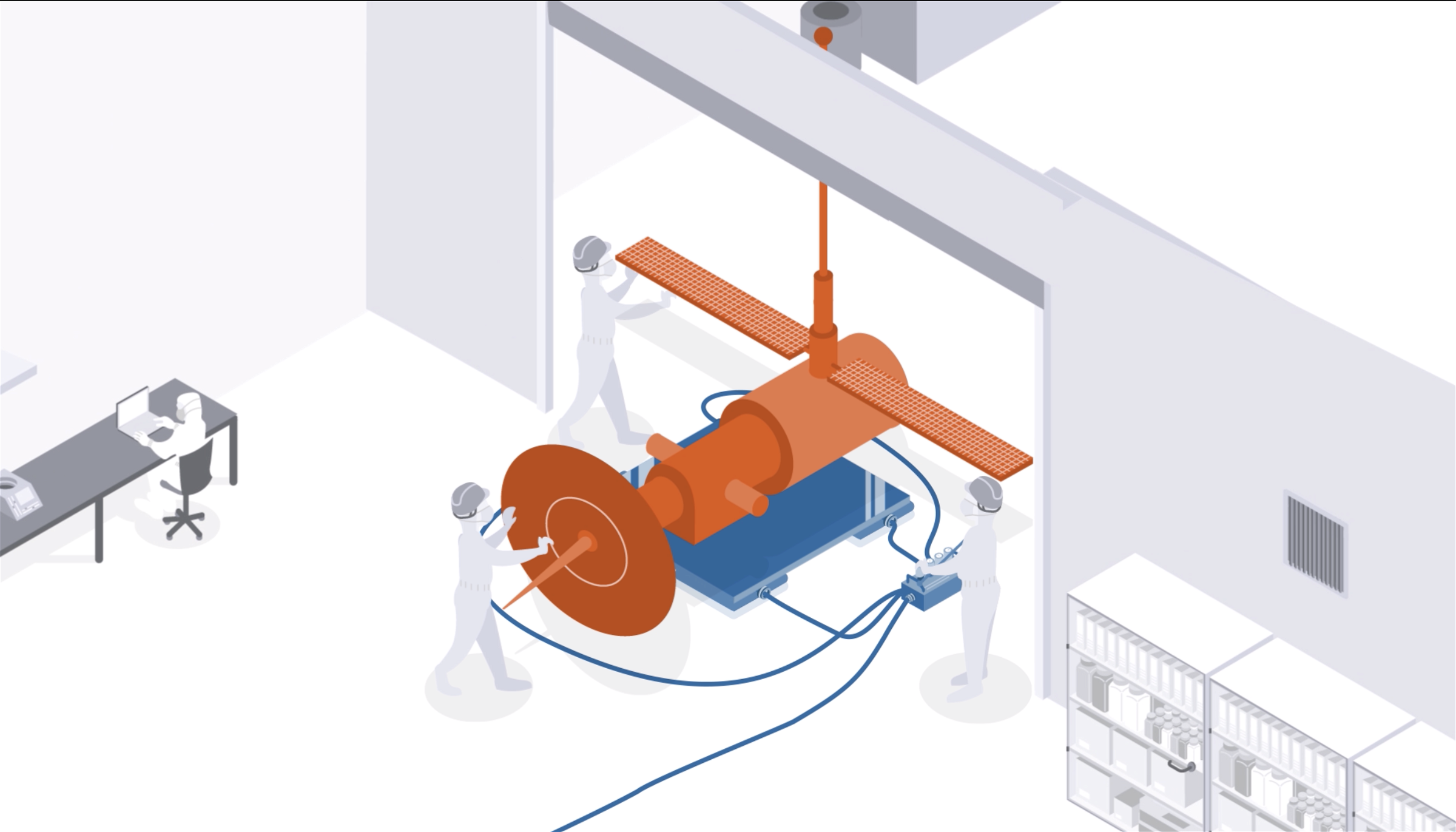

Air caster transport systems are used to move heavy and fragile laboratory equipment in and out of cleanrooms. Because there are no moving and wearing parts in air casters, they are ideal to use in a cleanroom environment. The only exhaust gas is the clean air that is inserted in the system.

Air Caster Modular Systems

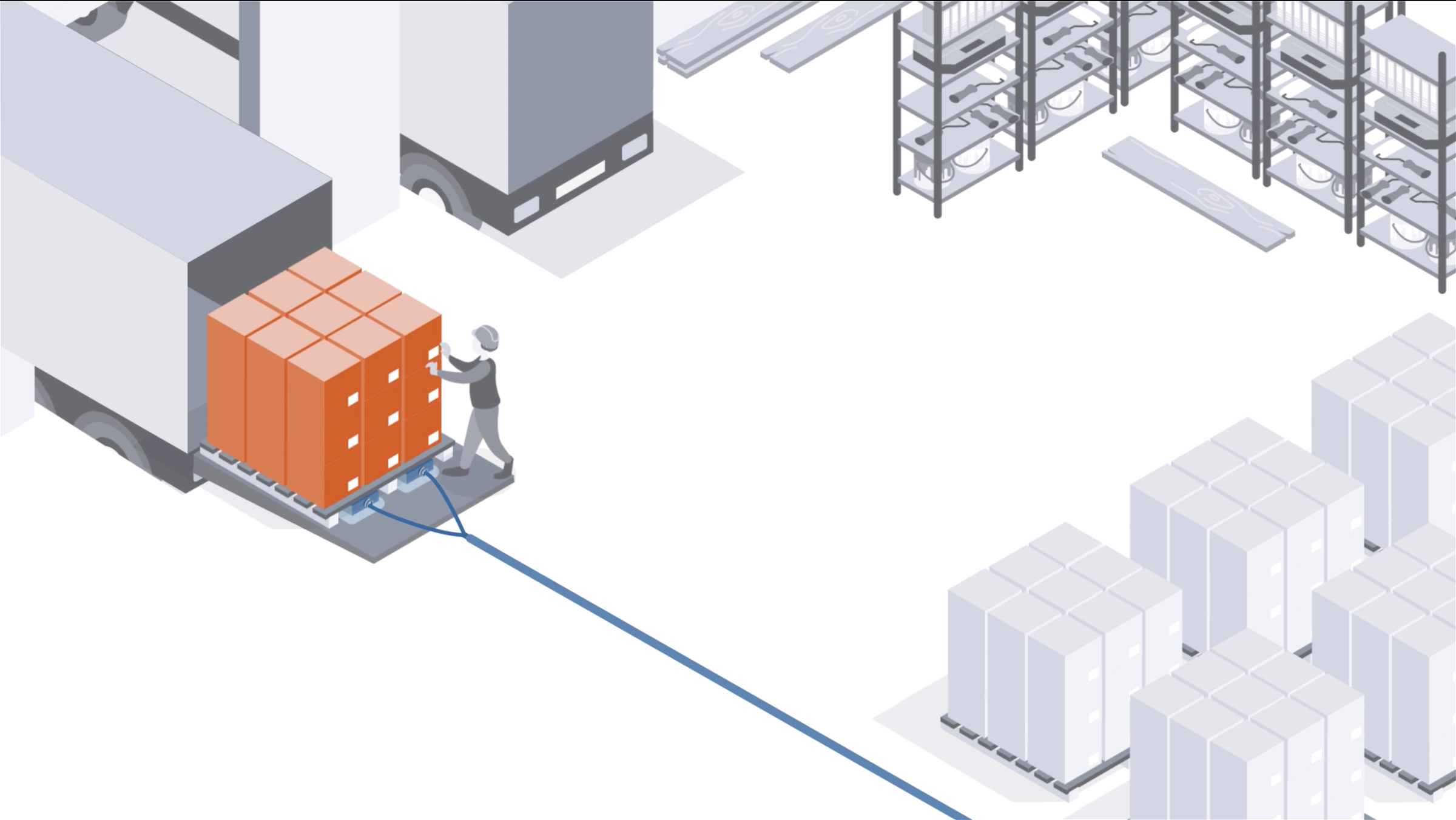

Air caster transport systems are used to quickly load and unload trucks in warehouses. The system can take out multiple pallets in one time to unload a truck in a single movement. This saves a lot of time per truckload.

Air Caster Modular Systems

Air caster transport systems are used to move fragile and valuable art and artifacts. Because there is no vibration during the movement, there is less risk of damage. The final positioning takes little time because of the freedom of movement.

Air Caster Modular Systems

Air caster transport devices are used to move heavy and large infrastructural objects. There are no permanent big structures needed for the transport. Just an air tight movement path and motorized vehicles to power the movement. This takes far less time then the traditional methods and less preparation.

Air Caster DIY Systems

Air caster DIY systems are used to move fragile, high-tech equipment within production facilities. There is no vibration during the movement that can cause serious damage to the electronics. Air caster systems are also used to transport the equipment to the end customer and do the final installation.

Air Caster DIY Systems

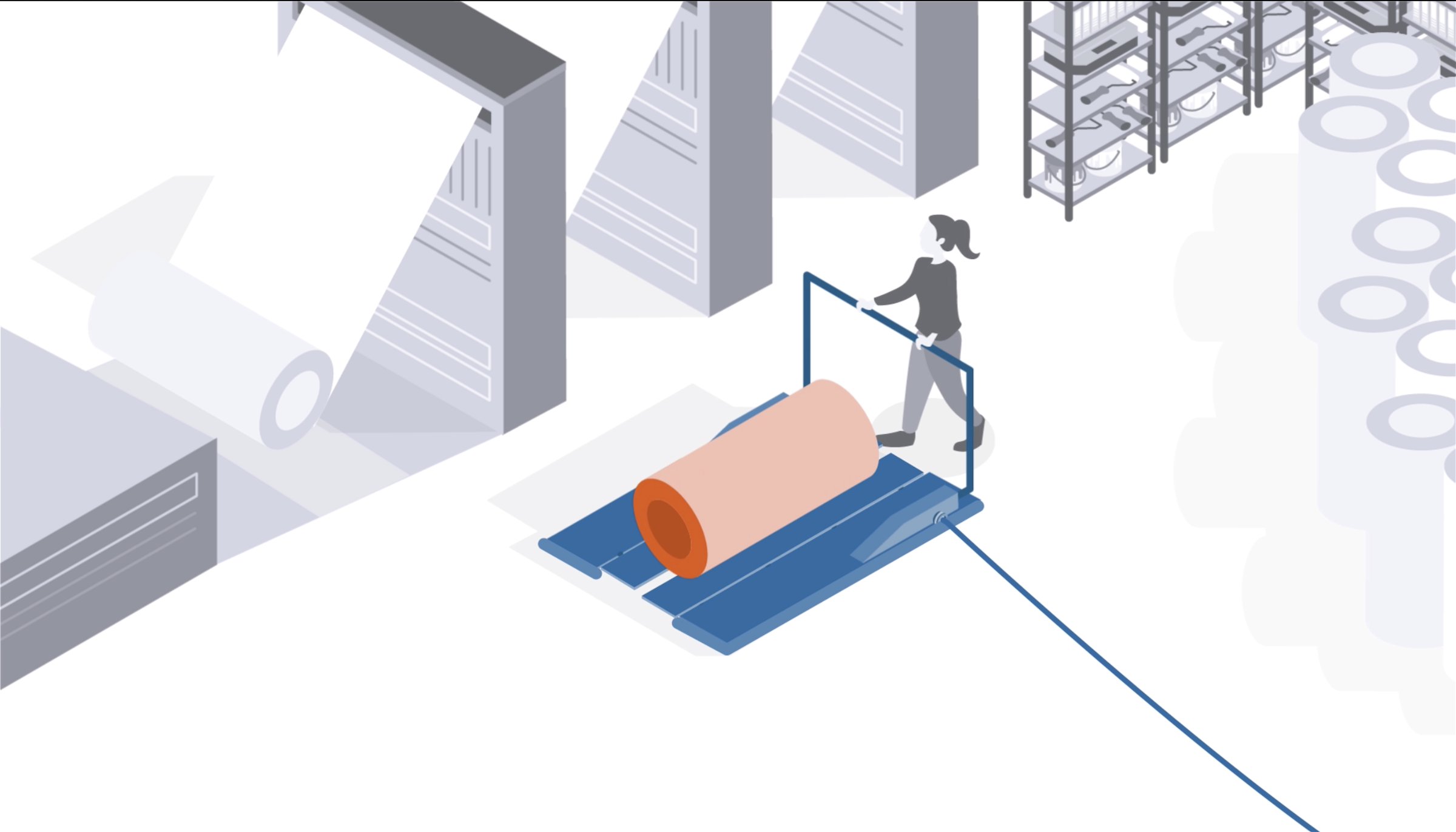

Air caster roll transporters are used to move heavy and large rolls and reels. These devices can pick up the rolls and move them ergonomically to the storage area or a production machine. It takes less personnel and the change-over is performed very quickly. Often one man can de the complete job.

Air Caster DIY Systems

Air caster transport systems are used to move moulds/ dies in-between production processes. Because the accuracy and freedom of movement, the changeover time is reduced to a fraction compared to traditional wheel or rail movement. This results in a higher production output.

Air Caster Modular Systems

Air caster transport systems are used in a variety of applications in the aircraft industry. From moving parts during production, to positioning the parts for assembly to even moving complete airplanes. The high capacity and freedom of movement save a lot of time during the complete production process.

Air Caster Modular Systems

Air caster transport systems are used to quickly store and pick up heavy and large machines in a warehouses. The machines can be unloaded and loaded into a truck quickly. Because of the omnidirectional movement they can be positioned very accurately and the storage space can be used very effectively.

Air Caster Modular Systems

Air caster transport systems are used in a variety of applications in the spacecraft industry. From moving parts during production in a cleanroom, to positioning the parts for assembly to even moving complete rockets for launch. The high capacity and freedom of movement save a lot of time during the complete production process.

Air Caster Modular Systems

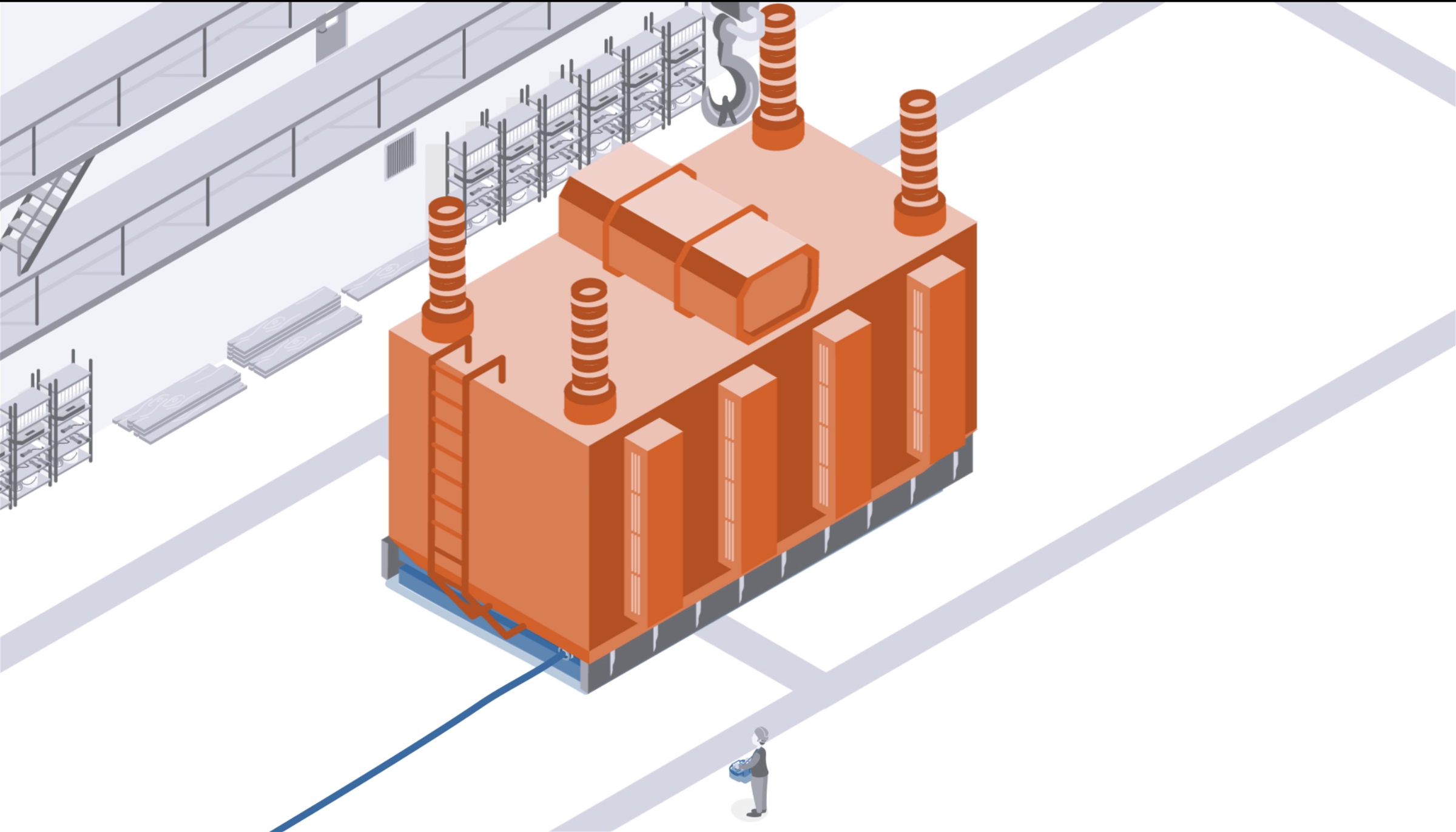

Air caster transport devices are used to move heavy transformers and their parts during production and final placement. Both the transformers and their often heavy parts are transported very efficiently because of the high capacity and freedom of movement of the air casters. This saves time (up to 30%) and prevents floor damage.

Air Caster DIY SystemsWe also produce and repair air casters that are compatible to other manufacturers at a very competitive price.

We only use high grade materials and process them on our precision machinery to produce constant, high quality products.

Our unique design allows all used materials to be recycled. Repairs and reconditioned air casters have a positive impact on the environment.