How can we help you?

Please contact us if you have questions about our products, the web shop or just need general advice. We are here to help!

The fascination for air caster transport and our technological passion is what drove us to re-invent the air bearing at Hover Transport Systems. We are specialized in manufacturing air caster solutions and small modular systems (air caster rigging systems) for internal transport. In our factory we can produce both the plastic and rubber types.

When complete transport vehicles are required, we partner up with a big machine builder that is specialized in manufacturing heavy transport machines. They can provide the right type of local support and service that is needed for this type of equipment.

Our belief is that focus will give the best results. In this regard we keep investing in the research and development of the air caster principle to make it even more durable and environmentally friendly. This all while keeping production costs as low as possible to make it accessible to a larger part of the industry.

Because of our flexible production plant, we are able to deliver all types of air casters that are compatible to other manufacturers in the market at a very competitive price.

We also came up with a unique production method that enables the base materials to be recyclable and cut costs for spare parts up to 50%!

We believe that we can make a premium quality product in an environmentally friendly way that is more cost effective than all other manufacturers to date.

We only use the most durable, high grade materials and process them on our precision machinery to produce constant, high quality products.

We have invented a more automated production process to the traditional one to make it more economical to produce, pack and ship the products.

We have a unique design that allows all base materials to be recycled and also reduces transport weight on products and spare parts.

We produce all types of air casters that are compatible to other manufacturers in the market.

A brief history of the invention of the air caster as a product and the development of our mother company Sakko.

Sakko is founded

Dirk Sakko founded the company Sakko for the coal trading business.

Domestic fuel oil

Sakko expanded their business by trading in domestic fuel oil.

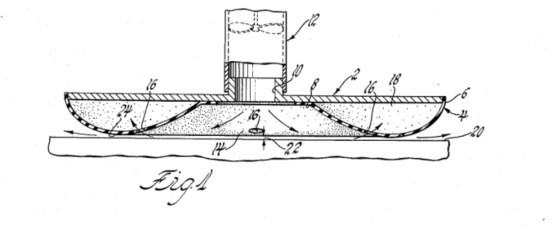

Invention of the Air Caster

The air caster is invented in 1966.

Start fuel activities

Sakko acquired own fuel storage facility. With a network of 55 petrol stations they became one of the largest independent suppliers in The Netherlands.

Sakko commercial

Sakko Commercial was founded to focus more on the business to business activities in fuel and other oil products.

Experience with air caster technology

From 2009 the founder of Hover Transport Systems gained experience in air caster technology, used to transport big transformers at ABB sites.

Orange Ventures is founded

Sakko co-founded Orange Ventures to broaden the activities and focus on innovation and sustainable technologies.

Hover Transport Systems is founded

In 2019 Hover Transport systems was founded within the Orange Ventures group. Focussed solely on air casters and related products, systems and spare parts.

Orange Charging is founded

Sakko steps into the electrical charging business for vehicles with a network of electrical charging stations.