Air casters are used in these applications

The usability of air casters is endless because there are so many advantages. We just want to sum up a few popular examples.

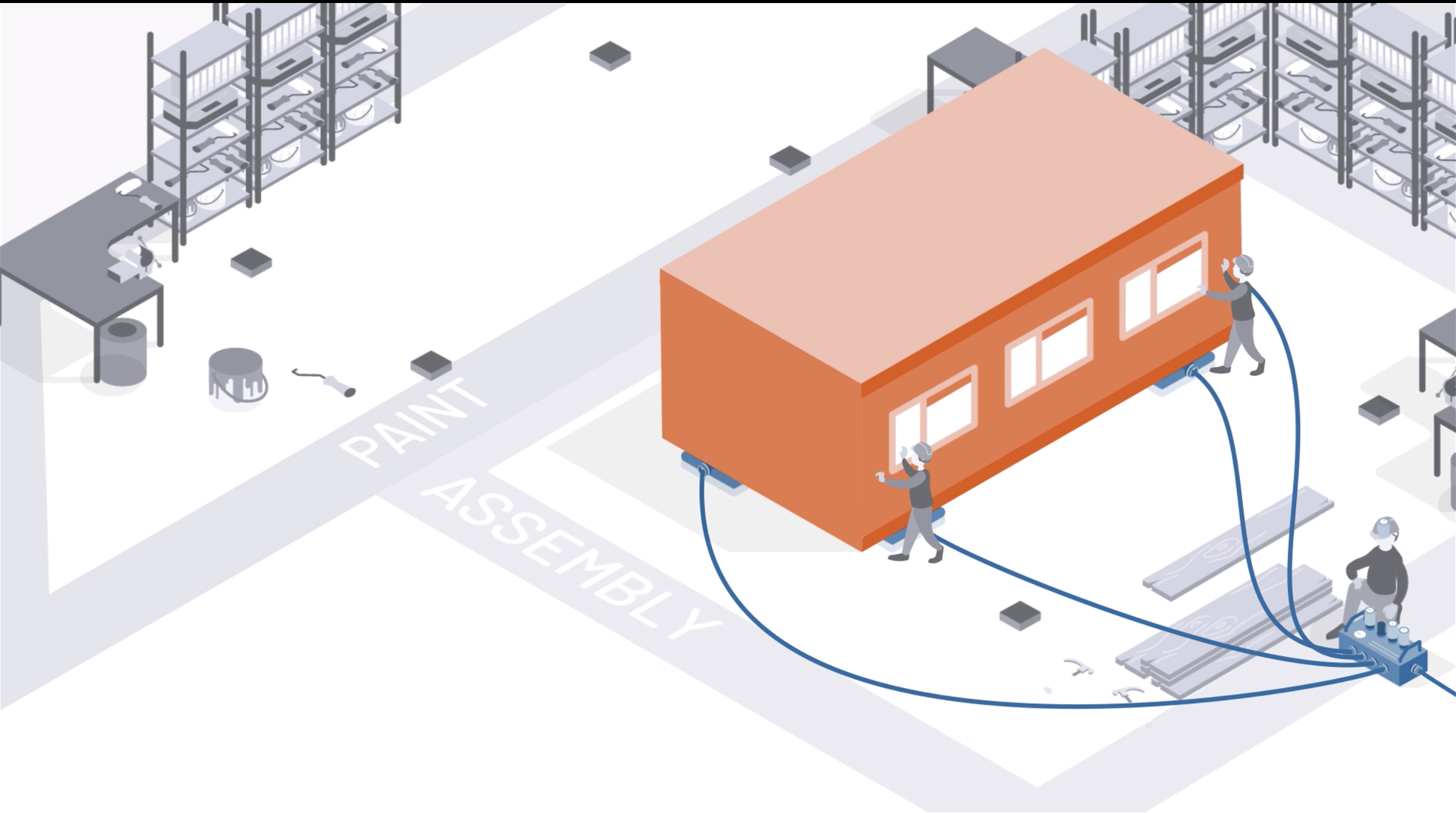

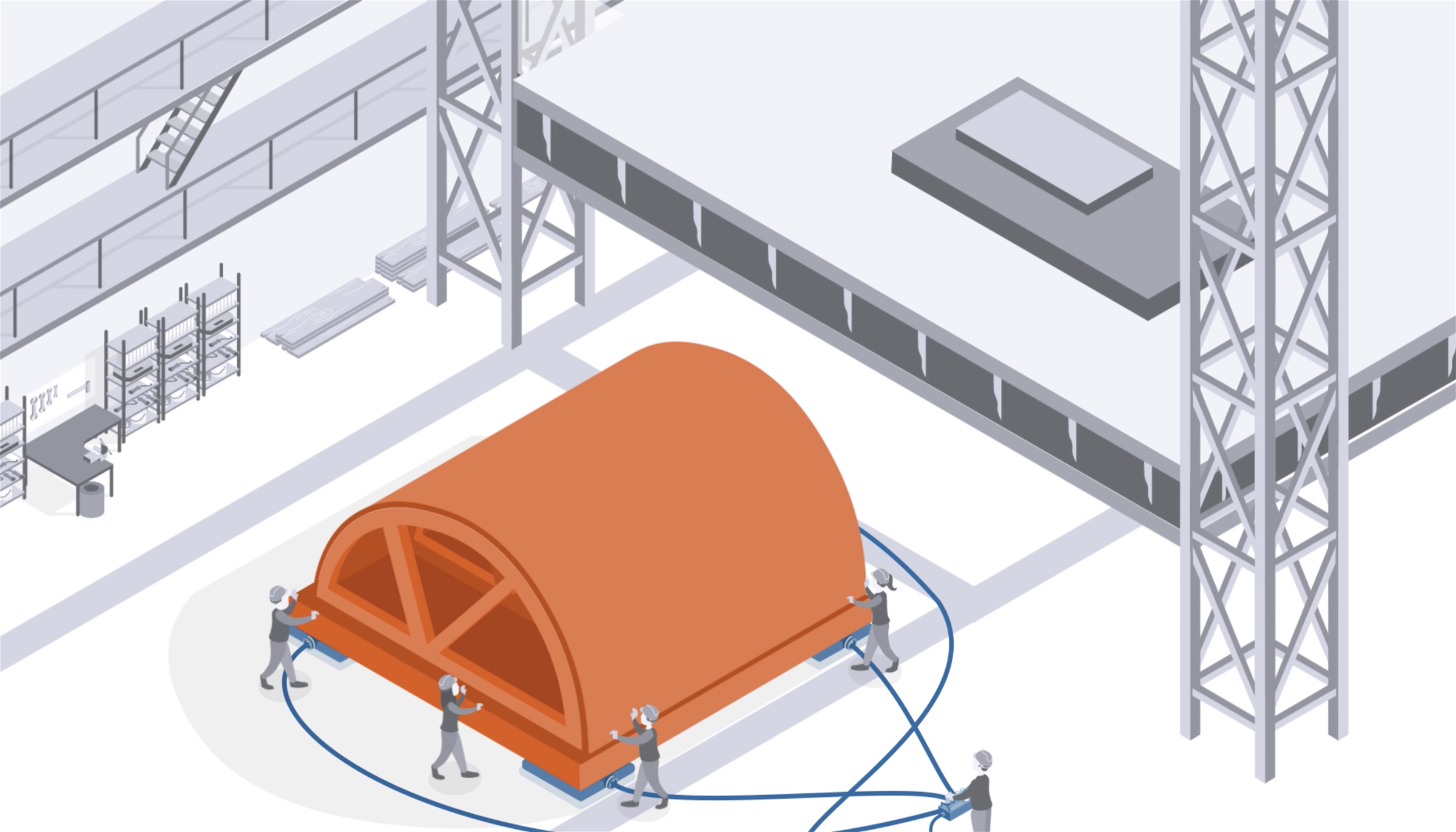

Move modular buildings during production

Air caster transport systems are used in modular building factories to easily move the structures between the different production stations. This reduces the transport time by 40% compared to traditional methods. The working staff can move the structures themselves in an ergonomic way. No permanent installations needed.

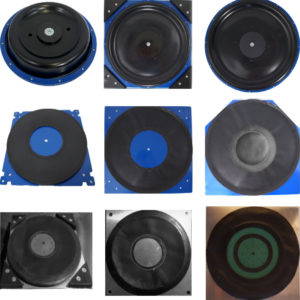

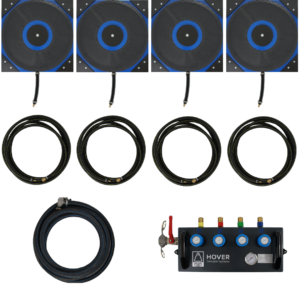

Air Caster Modular Systems

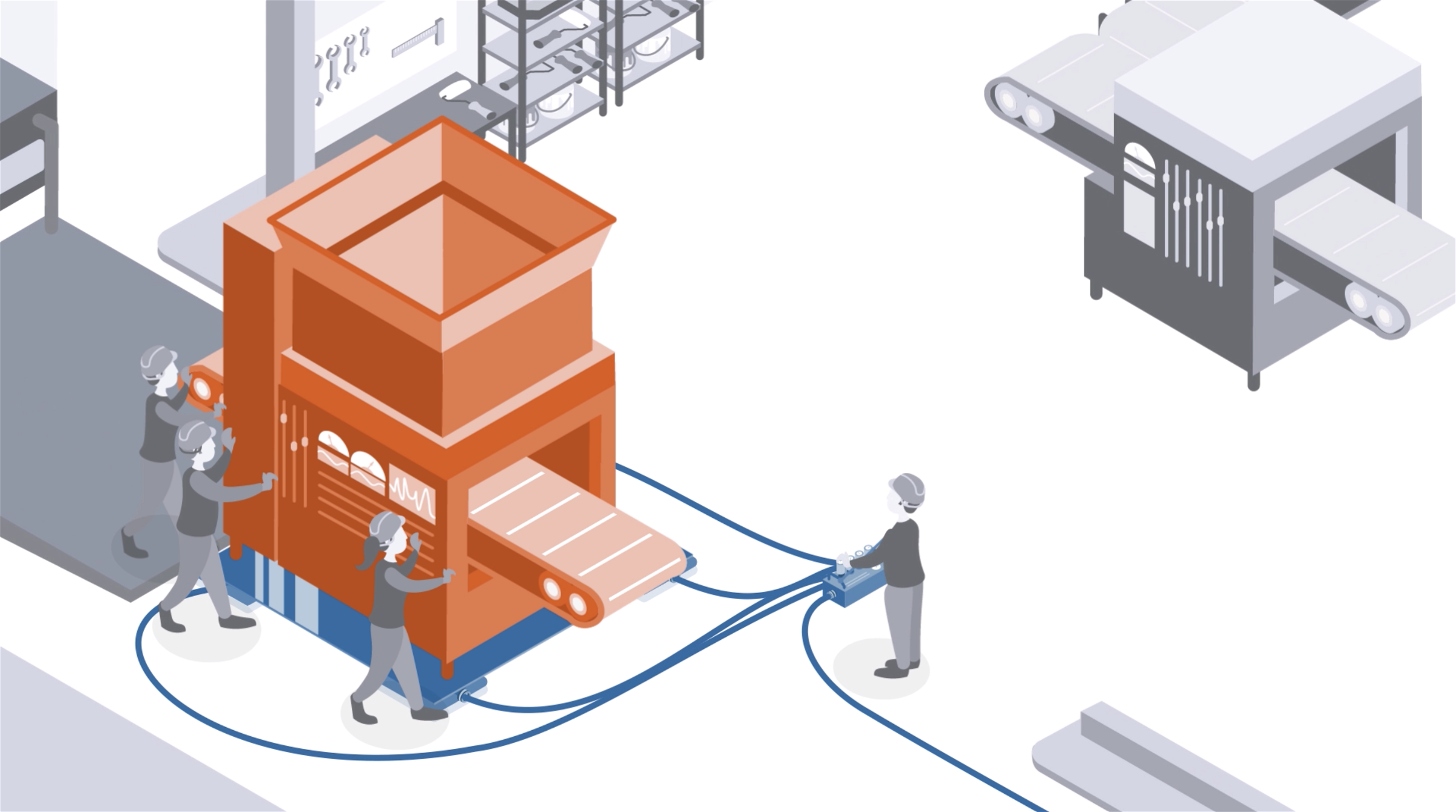

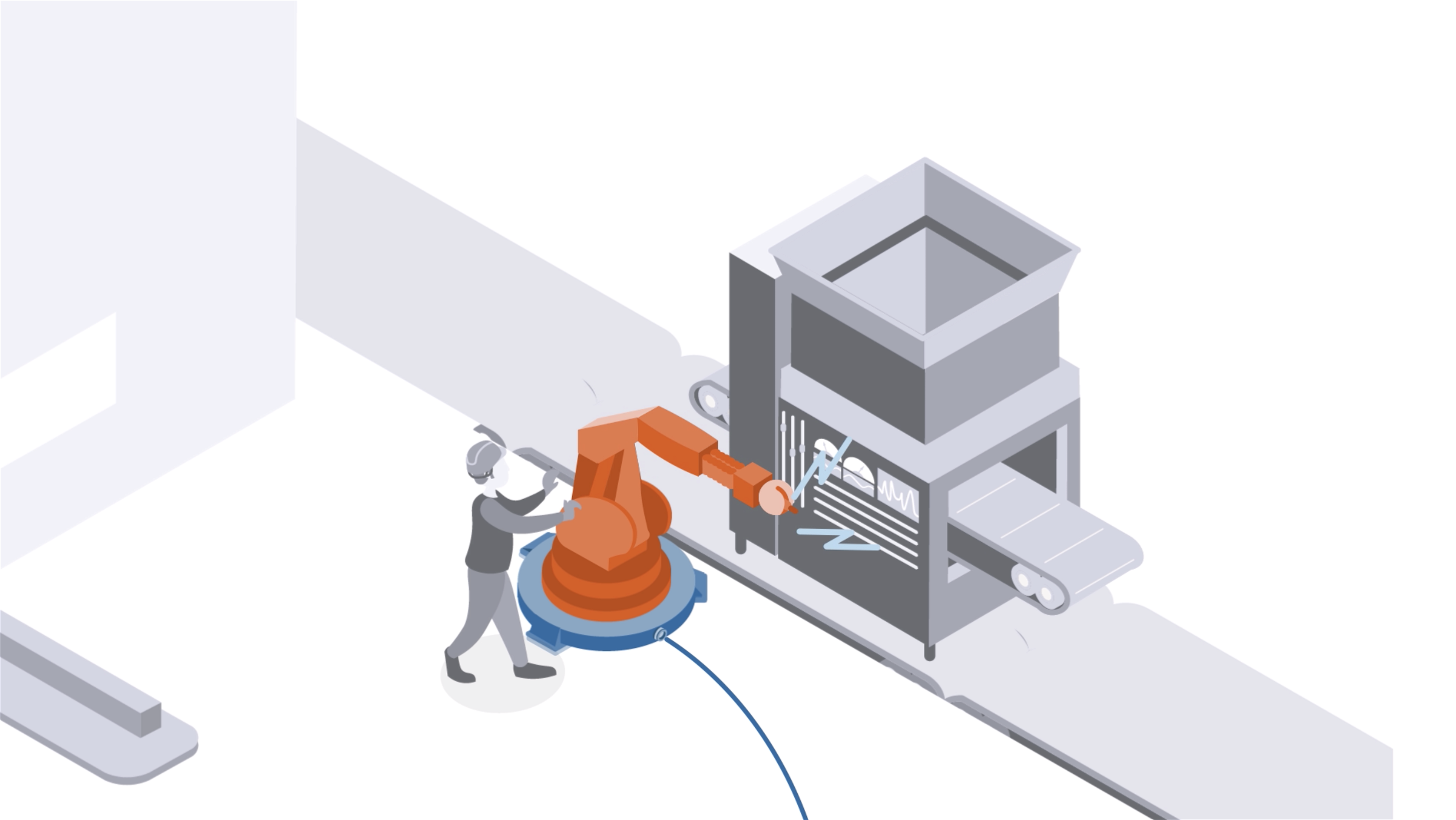

Move and position heavy machines

Air caster transport systems are used to relocate or install large and heavy machines. Compared to traditional methods this only takes a fraction of the time. Both the movement and final positioning are quicker because the system hovers above the floor. After the movement the system can easily be stored in the transport case.

Air Caster Modular Systems

Move heavy production tools

Air caster DIY systems are permanently installed into some heavy or large production tools. This makes the production process more flexible to better meet the markets requirements. Because the air casters are embedded in the tools, you just need to connect the air supply and the system is ready to go.

Air Caster DIY Systems

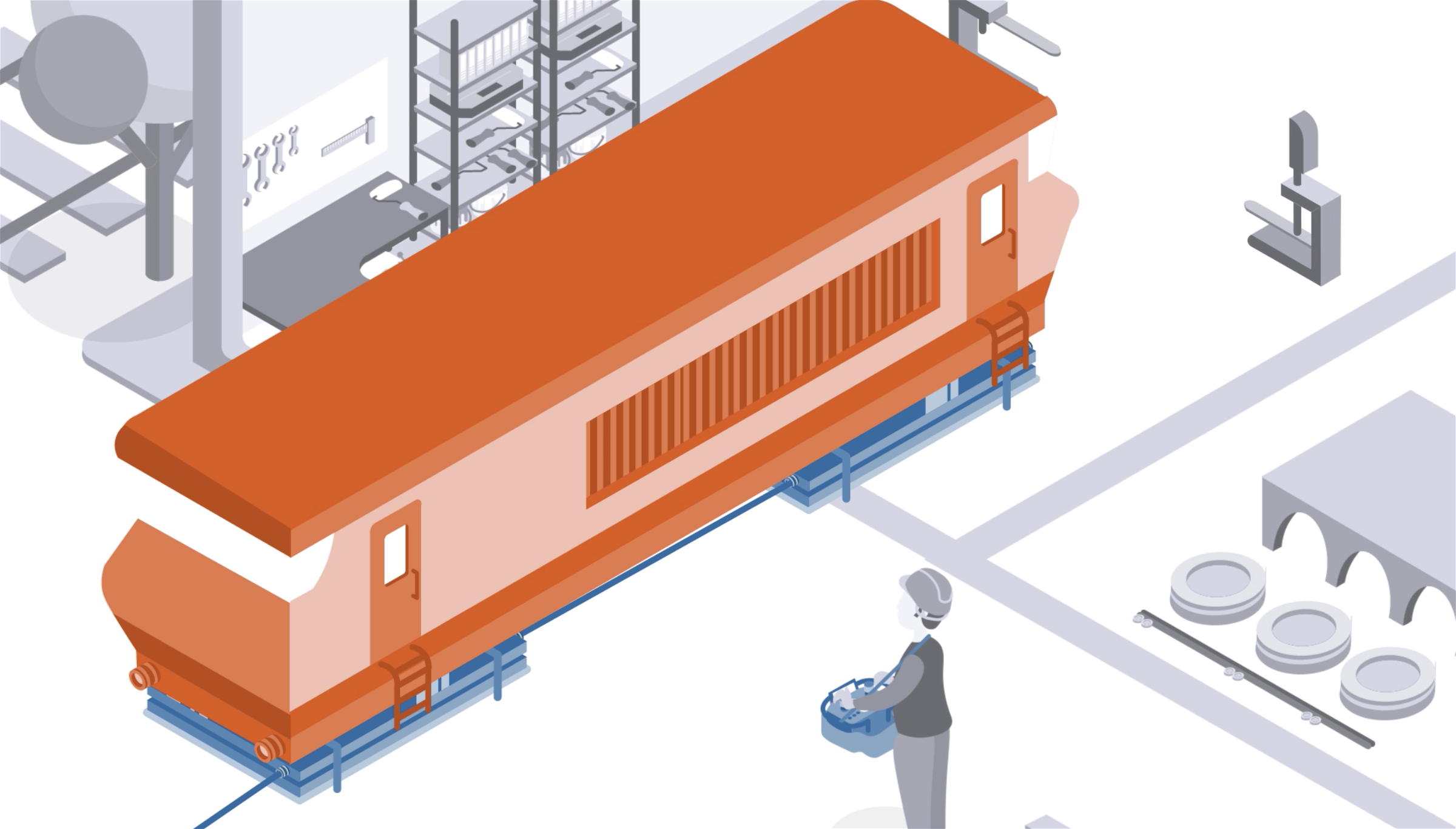

Move locomotives and heavy vehicles during production or revision

Air caster transport devices are used to move heavy locomotives and other vehicles during production or revision. Both the vehicles and their often heavy parts are transported very efficiently because of the high capacity and freedom of movement of the air casters. This saves time (often up to 30%) and prevents floor damage.

Air Caster DIY Systems

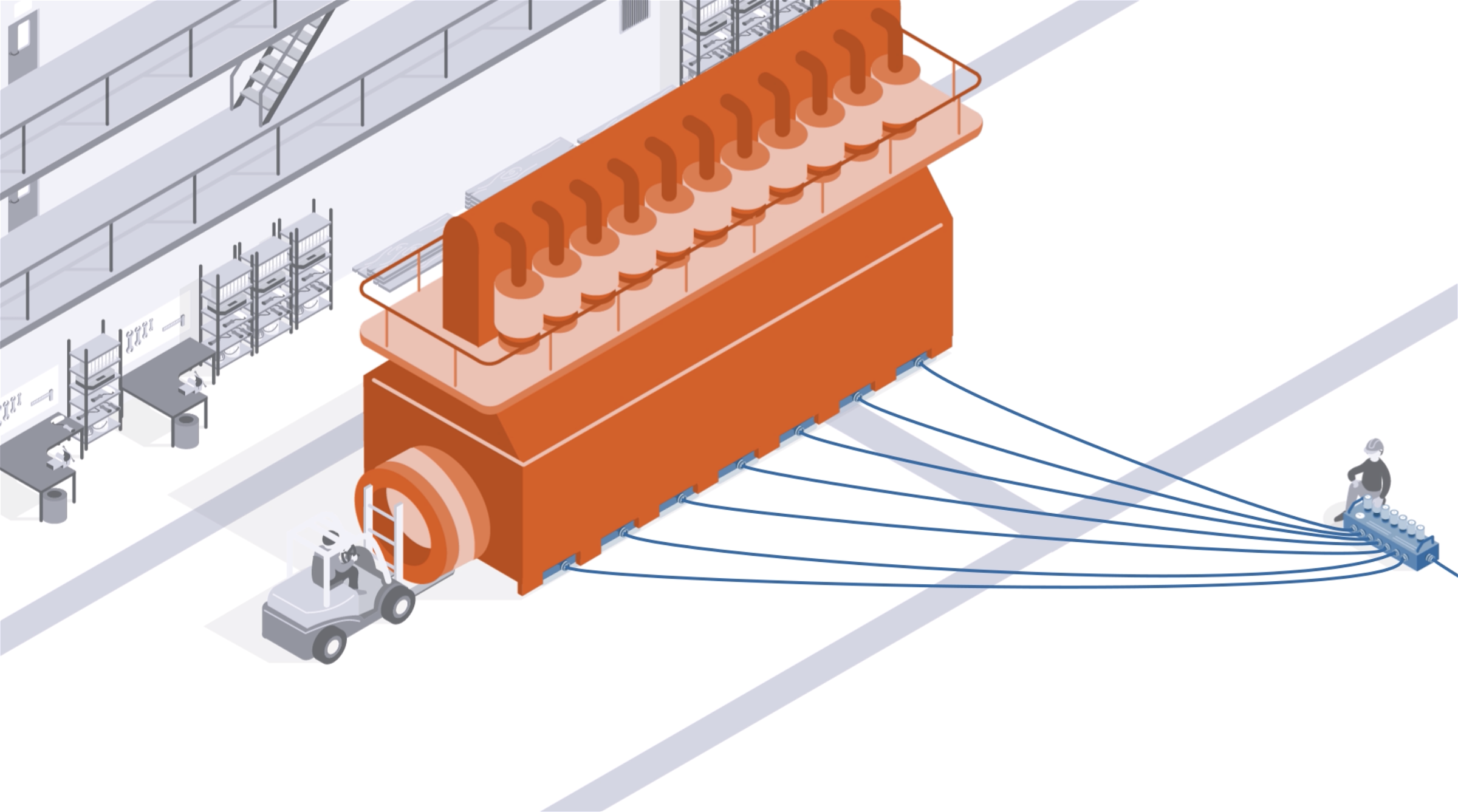

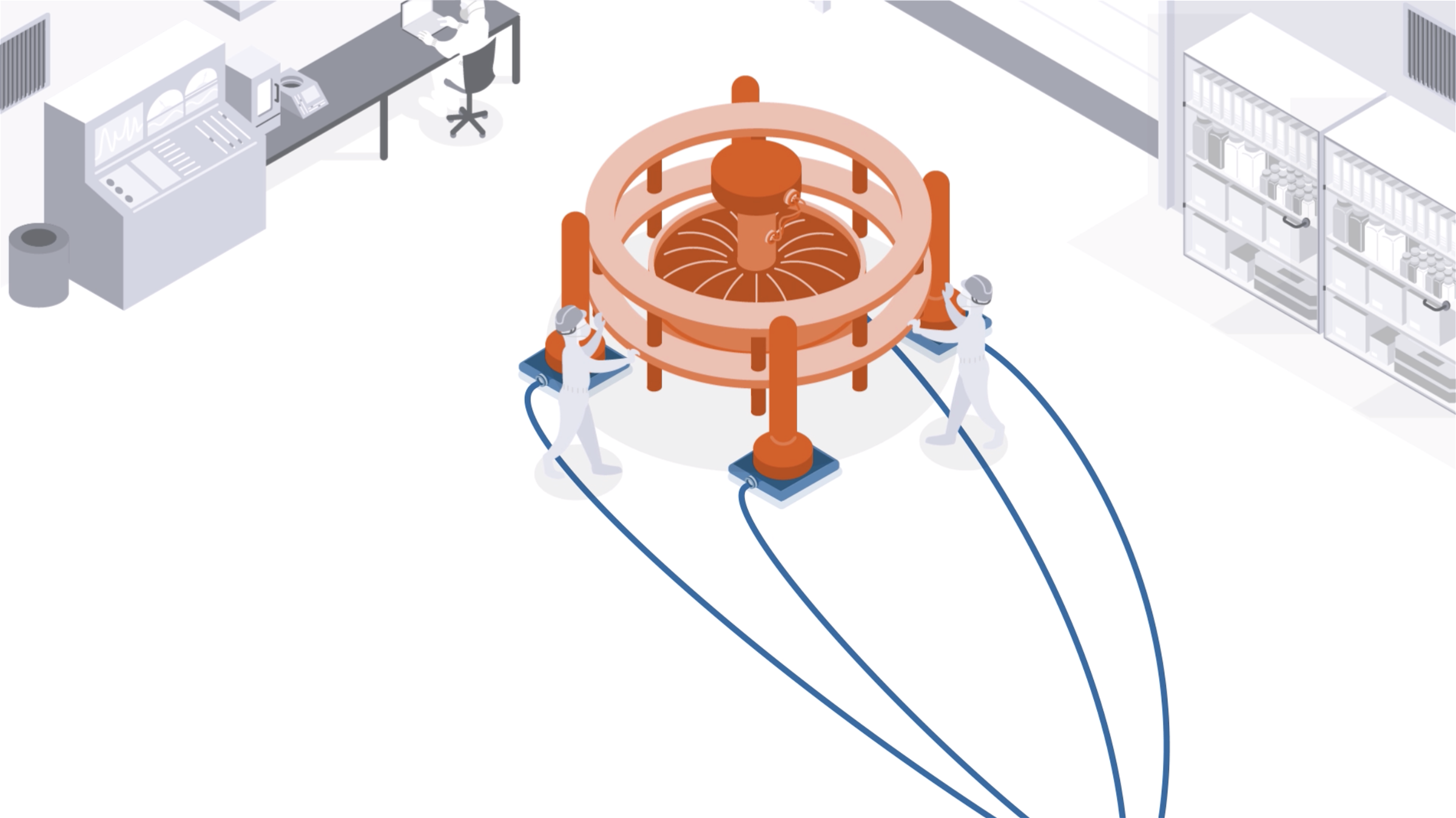

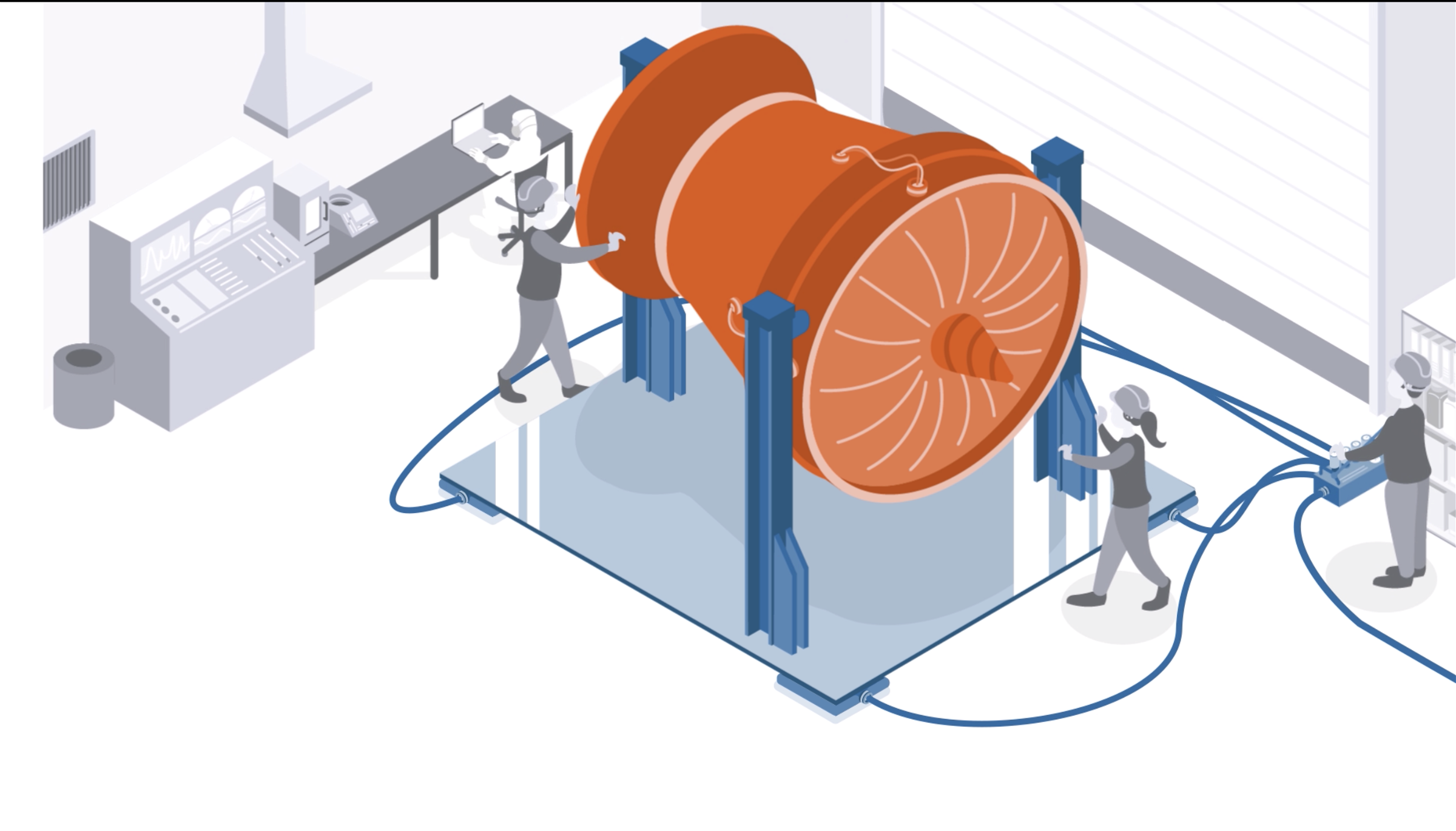

Move big engine during production or revision

Air caster transport systems are used to move big engines and parts during production or revision. Big engines often have heavy parts that need to be placed very accurately. The use of air casters saves a lot of time in the (final) positioning of these parts because of the omnidirectional movement. Takes less time and less manpower.

Air Caster Modular Systems

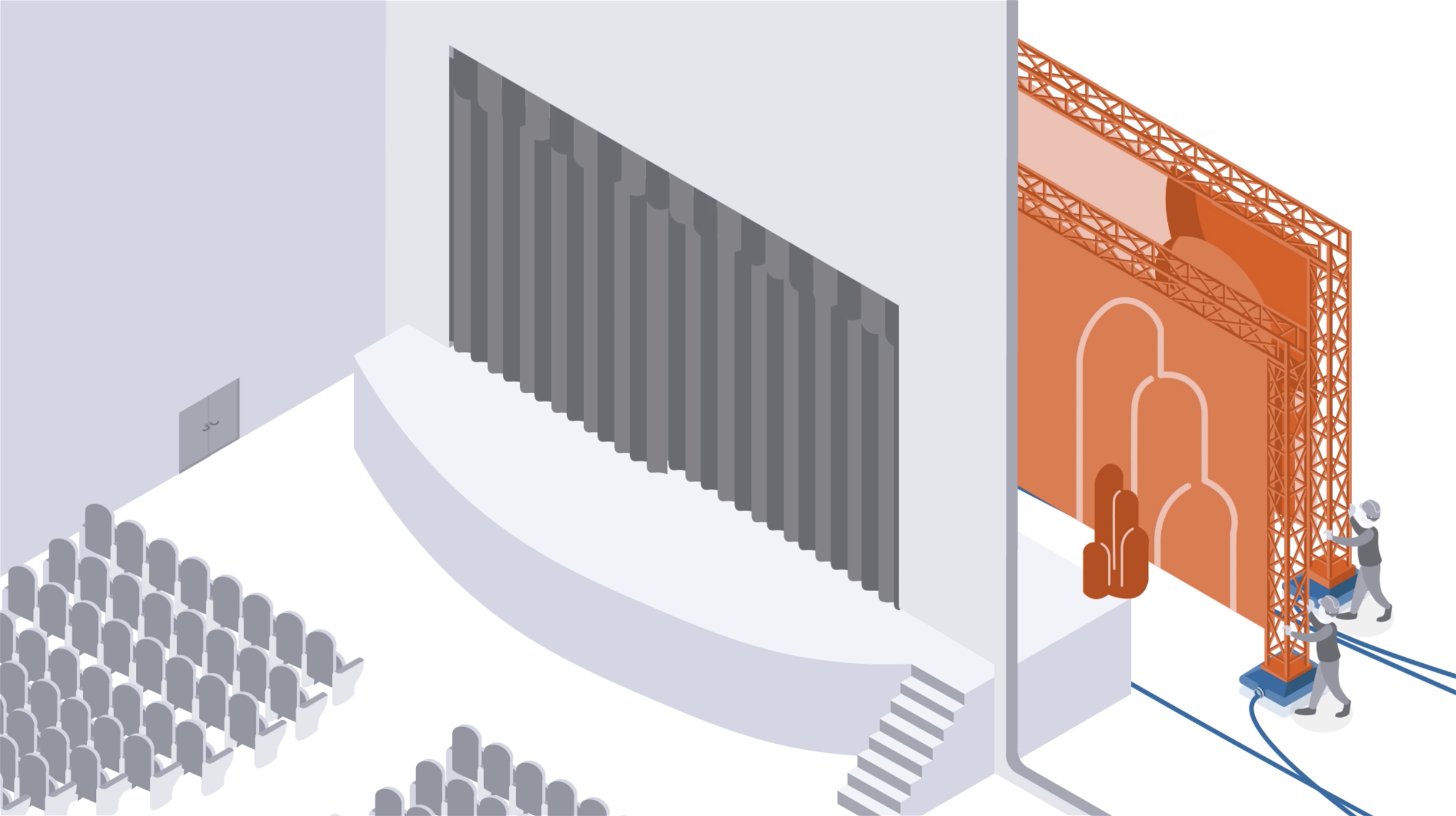

Move theater sceneries

Air caster DIY systems are used to move theatre sceneries behind the curtains. The changement can be performed very quickly because the air casters are already installed and can be moved by the theatre staff themselves. In an ergonomic way because of the low friction of the system.

Air Caster DIY Systems

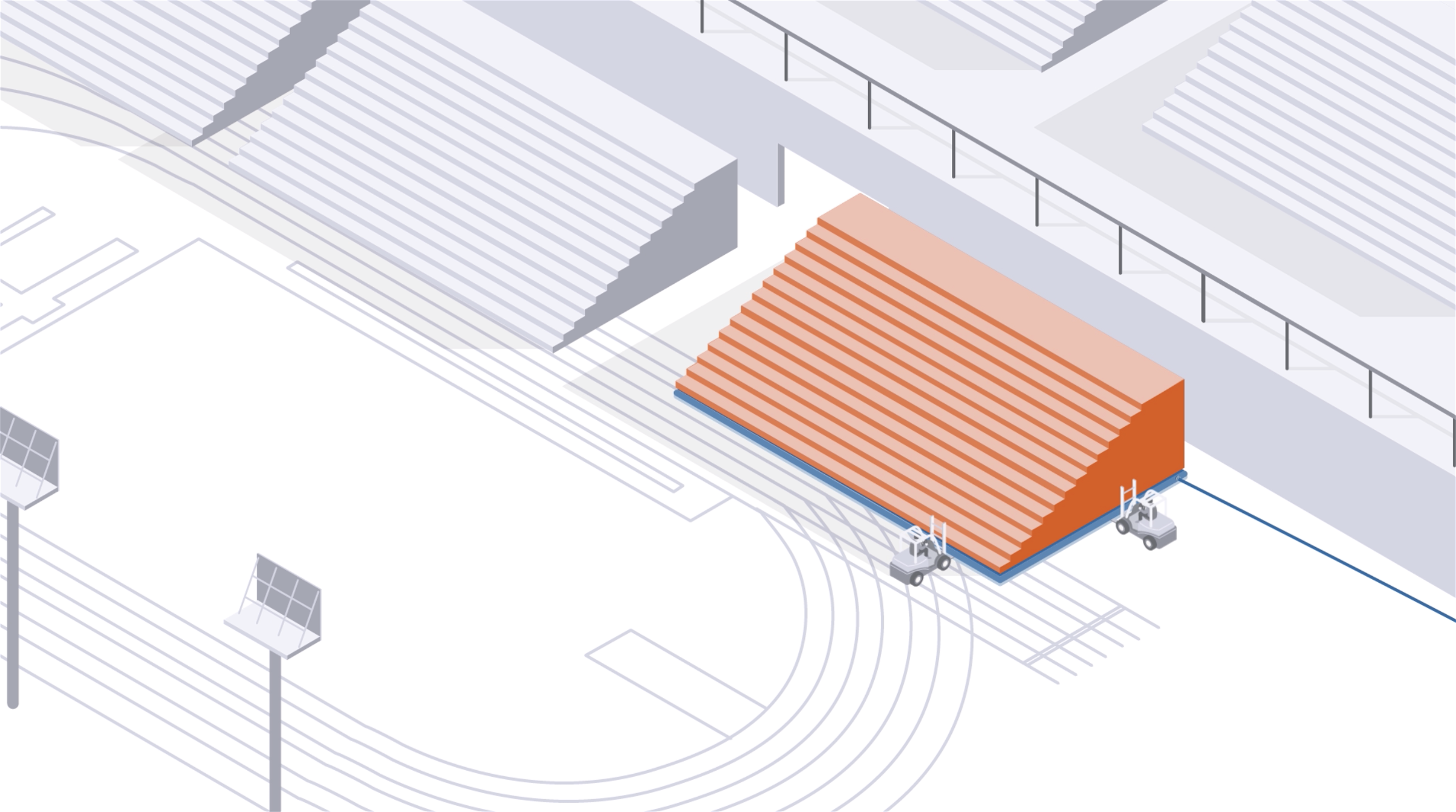

Move stadium seating modules

Air caster DIY systems are used to move big stadium seating modules. The change over time between different stadium setting is crucial in making a stadium multi purpose. These changes can be made quicker using air caster technology, up to 40%.

Air Caster DIY Systems

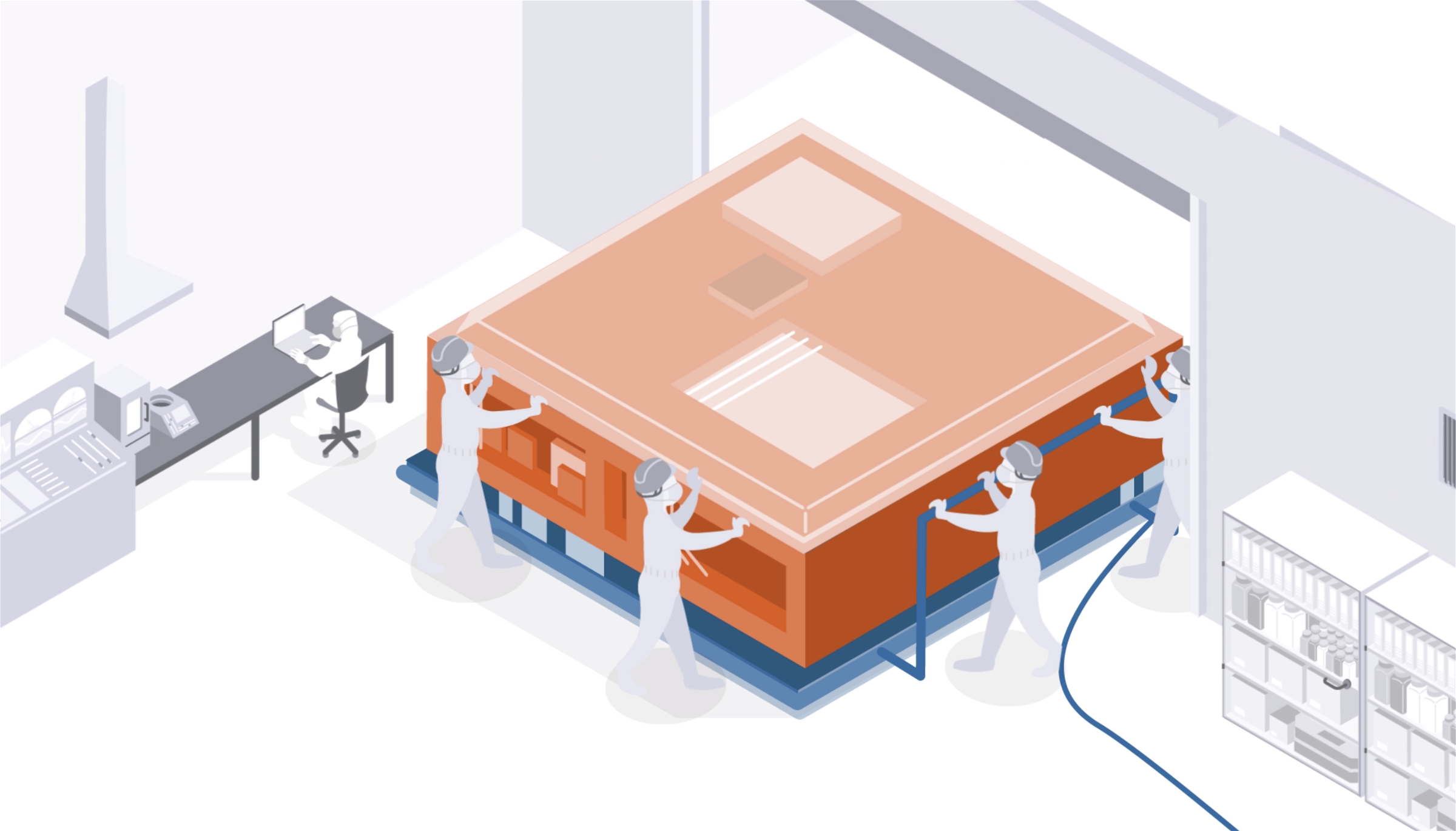

Move heavy laboratory equipment in a cleanroom

Air caster transport systems are used to move heavy and fragile laboratory equipment in and out of cleanrooms. Because there are no moving and wearing parts in air casters, they are ideal to use in a cleanroom environment. The only exhaust gas is the clean air that is inserted in the system.

Air Caster Modular Systems

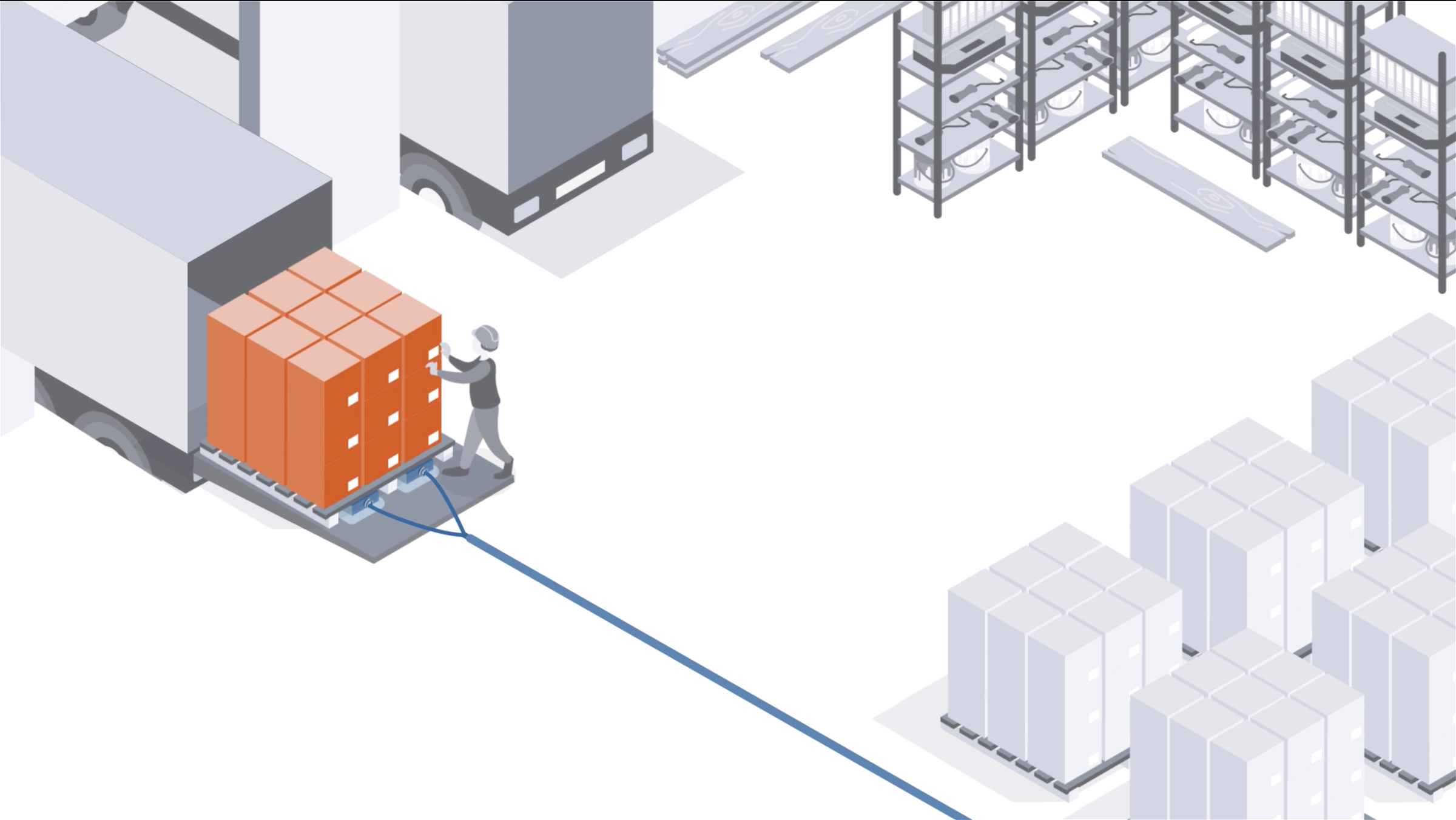

Move loaded pallets in truck or warehouse

Air caster transport systems are used to quickly load and unload trucks in warehouses. The system can take out multiple pallets in one time to unload a truck in a single movement. This saves a lot of time per truckload.

Air Caster Modular Systems

Move fragile art and artifacts

Air caster transport systems are used to move fragile and valuable art and artifacts. Because there is no vibration during the movement, there is less risk of damage. The final positioning takes little time because of the freedom of movement.

Air Caster Modular Systems

Move heavy infrastructural objects

Air caster transport devices are used to move heavy and large infrastructural objects. There are no permanent big structures needed for the transport. Just an air tight movement path and motorized vehicles to power the movement. This takes far less time then the traditional methods and less preparation.

Air Caster DIY Systems

Move fragile, high-tech equipment during production

Air caster DIY systems are used to move fragile, high-tech equipment within production facilities. There is no vibration during the movement that can cause serious damage to the electronics. Air caster systems are also used to transport the equipment to the end customer and do the final installation.

Air Caster DIY Systems

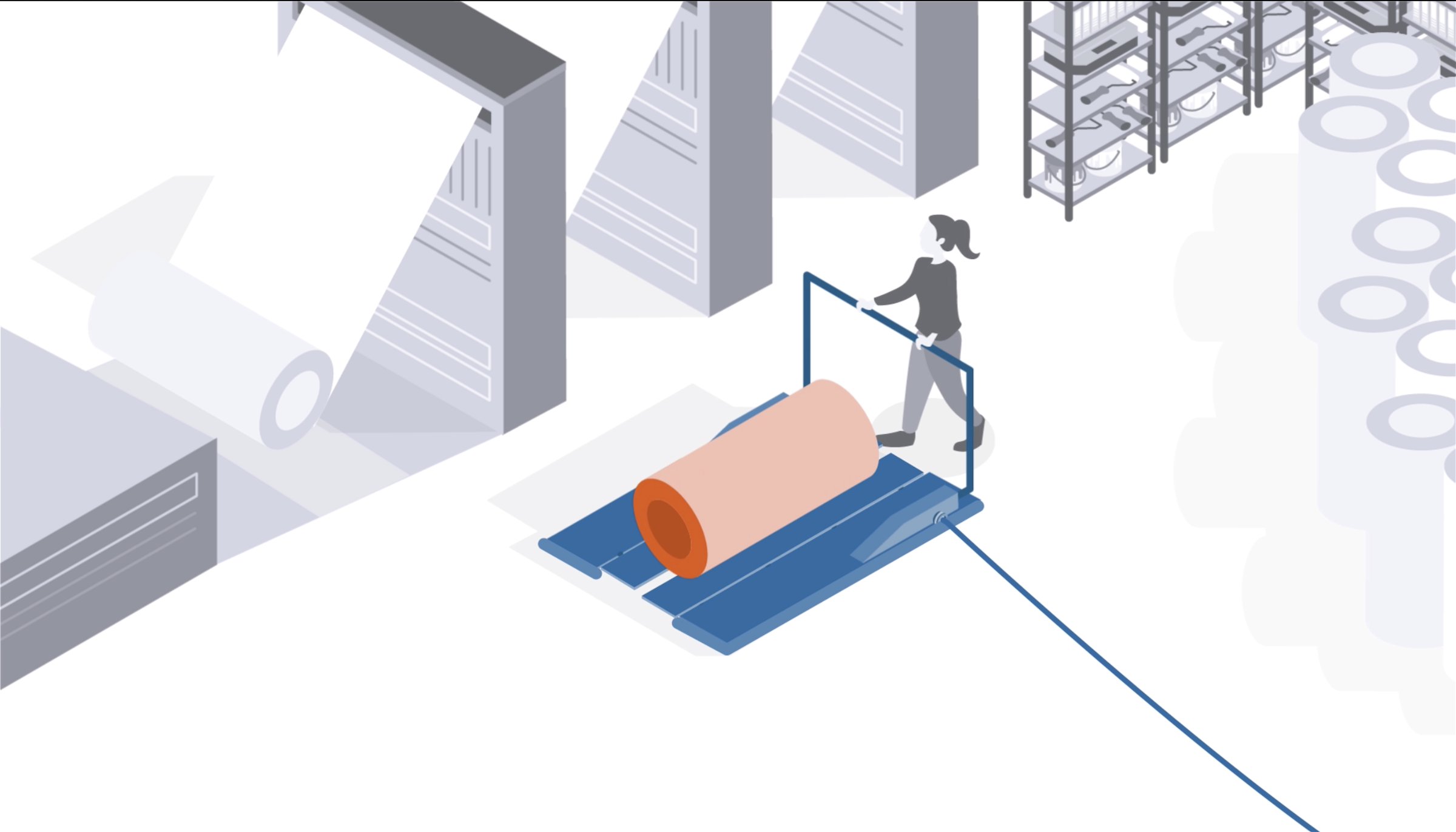

Move heavy and large rolls and reels

Air caster roll transporters are used to move heavy and large rolls and reels. These devices can pick up the rolls and move them ergonomically to the storage area or a production machine. It takes less personnel and the change-over is performed very quickly. Often one man can de the complete job.

Air Caster DIY Systems

Move heavy moulds and dies

Air caster transport systems are used to move moulds/ dies in-between production processes. Because the accuracy and freedom of movement, the changeover time is reduced to a fraction compared to traditional wheel or rail movement. This results in a higher production output.

Air Caster Modular Systems

Move aircraft (parts) and engines during production or revision

Air caster transport systems are used in a variety of applications in the aircraft industry. From moving parts during production, to positioning the parts for assembly to even moving complete airplanes. The high capacity and freedom of movement save a lot of time during the complete production process.

Air Caster Modular Systems

Move machines in and out of storage

Air caster transport systems are used to quickly store and pick up heavy and large machines in a warehouses. The machines can be unloaded and loaded into a truck quickly. Because of the omnidirectional movement they can be positioned very accurately and the storage space can be used very effectively.

Air Caster Modular Systems

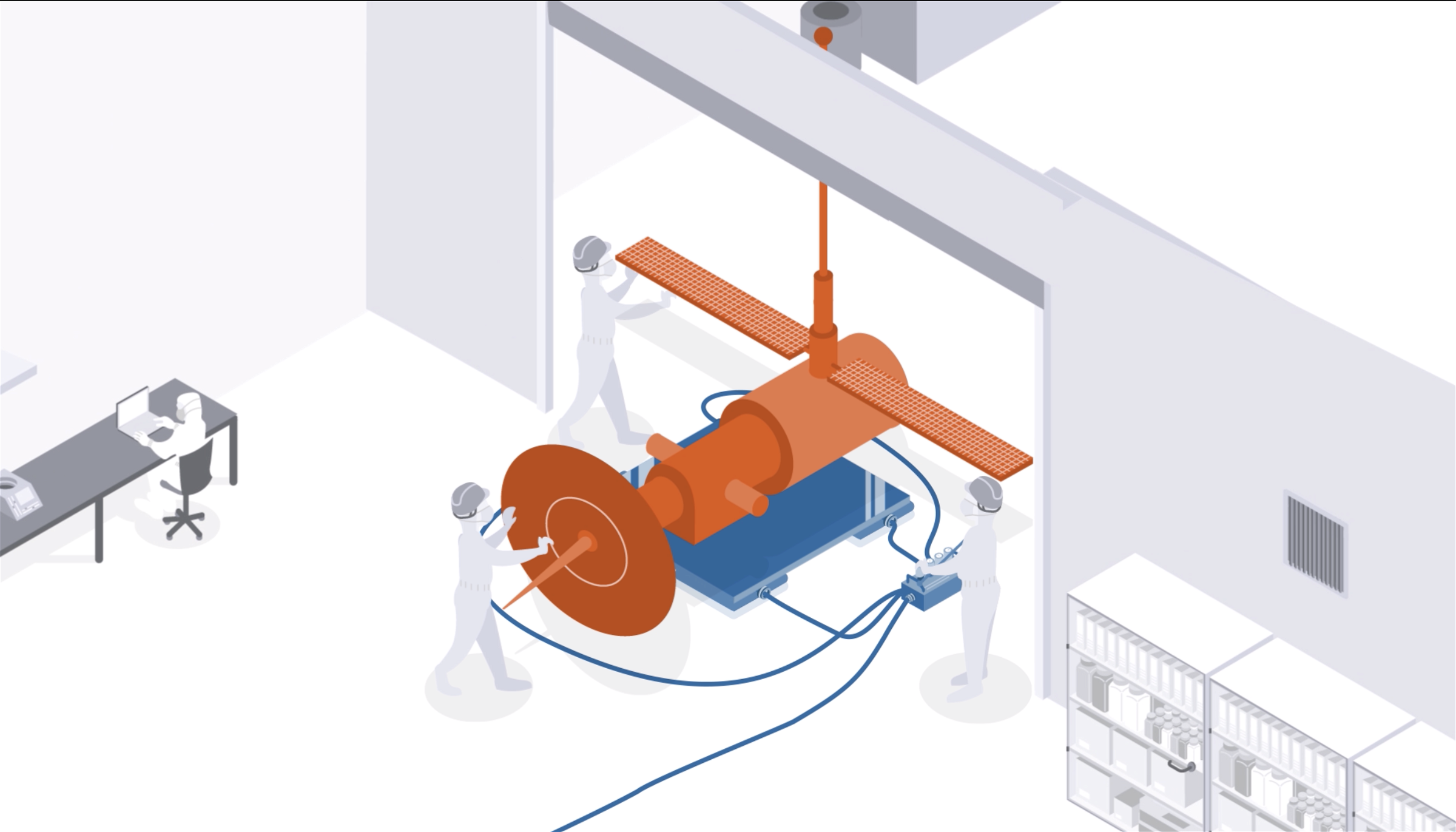

Move spacecraft equipment during production in a cleanroom

Air caster transport systems are used in a variety of applications in the spacecraft industry. From moving parts during production in a cleanroom, to positioning the parts for assembly to even moving complete rockets for launch. The high capacity and freedom of movement save a lot of time during the complete production process.

Air Caster Modular Systems

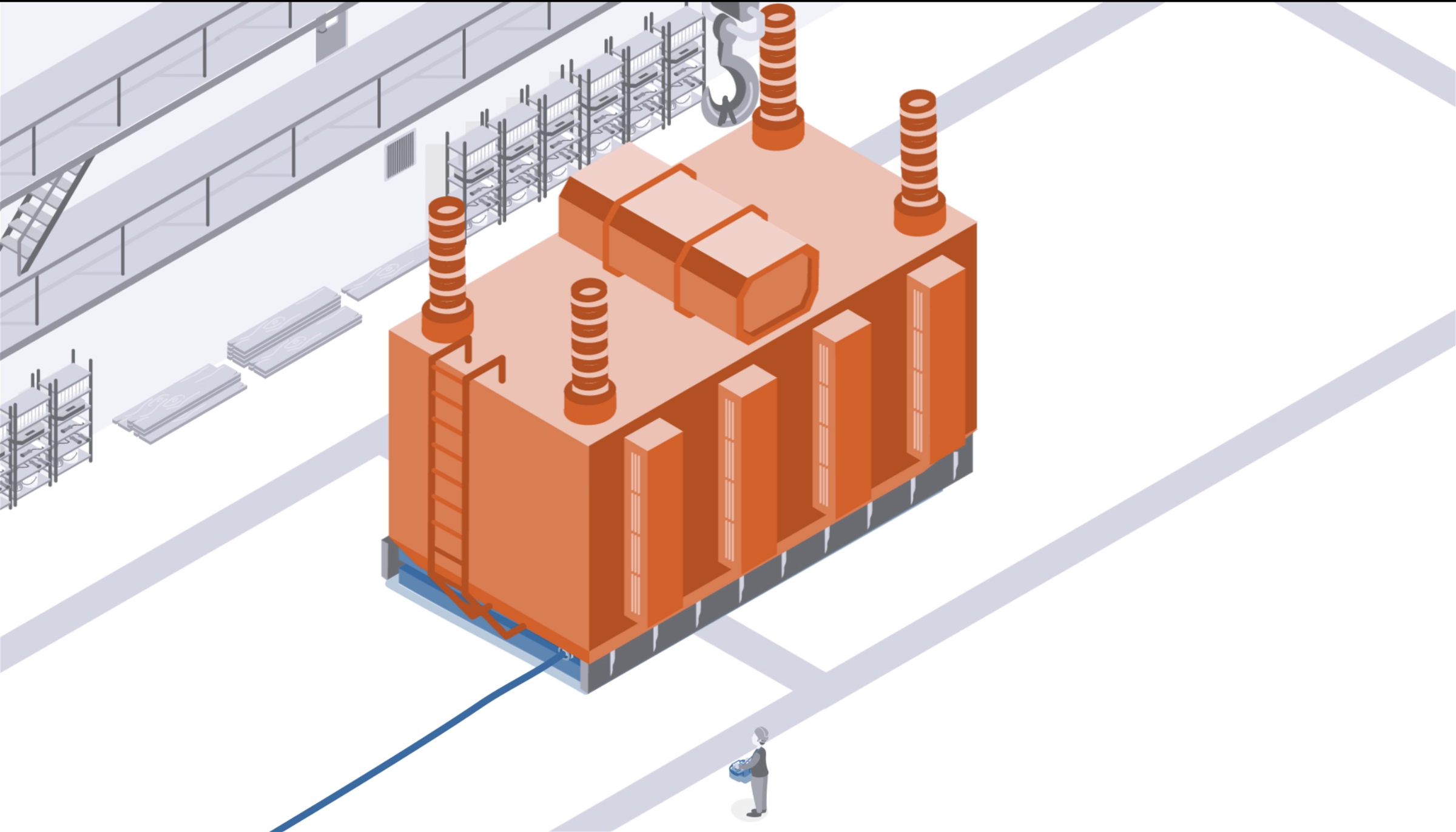

Move heavy transformers during production

Air caster transport devices are used to move heavy transformers and their parts during production and final placement. Both the transformers and their often heavy parts are transported very efficiently because of the high capacity and freedom of movement of the air casters. This saves time (up to 30%) and prevents floor damage.

Air Caster DIY Systems